About OK JAWS

How Plastic Injection Molding Powers OKJAWS Steering Wheel Knobs

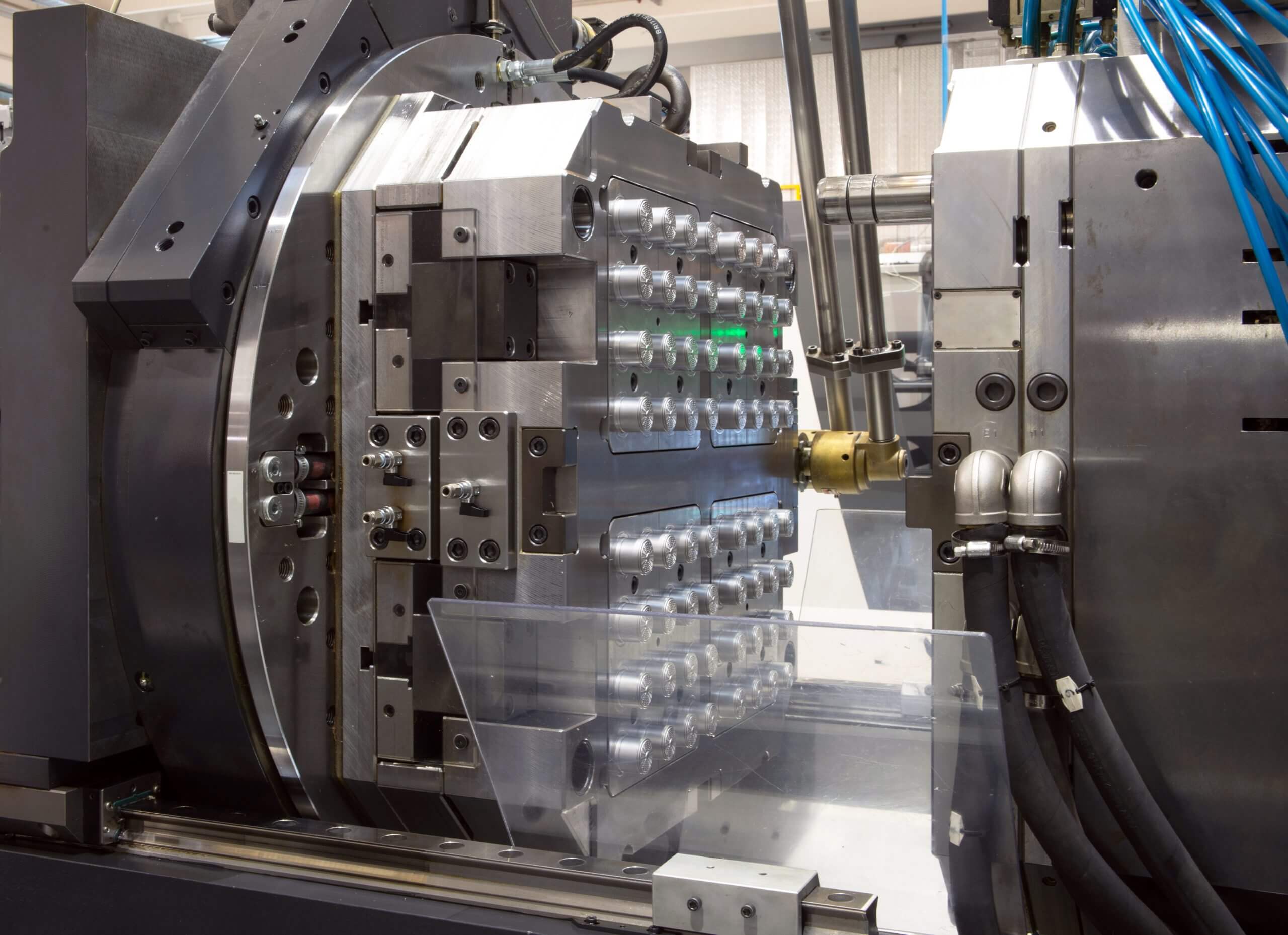

Plastic injection molding is a precise and efficient method used to mass-produce durable plastic components. It involves melting plastic pellets and injecting the material into a mold under high pressure. Once cooled, the mold opens and the part is released—ready for use.

At OKJAWS , we rely on advanced injection molding technology to achieve accurate shapes, smooth finishes, and long-lasting durability. But what sets OKJAWS apart is our strict quality control throughout every step of production:

- We begin with premium plastic materials, chosen for strength and heat resistance.

- Our molds are precision-engineered and regularly maintained to ensure consistency.

- We monitor key production factors—such as temperature, pressure, and cycle time—to avoid defects.

- Each knob is individually inspected and tested for rotation smoothness, grip comfort, and structural integrity.

Thanks to our attention to detail and production standards, OKJAWS knobs perform reliably—even under extreme heat or long-term use. This is why our products are recognized globally, including earning Amazon Best Seller status through our partner brand, Hypersonic.

For businesses seeking a trusted supplier of steering wheel knobs, OKJAWS is the expert partner you can count on—offering innovation, quality, and service you can rely on.

Why Choose Us

Three step of plastic molding injection

Step 1

Melting and Injection

Step 2

Cooling and Solidifying

Step 3

Mold Opening and Ejection

Join The Success

See how our solution can work for your team.

Schedule a free consultation with our team and let’s make things happen!