Table of Contents

ToggleAbstract

In today’s globalized and highly competitive supply chain, Taiwan quality has emerged as a benchmark for reliability, innovation, and long-term brand value. This article explores how Taiwan’s manufacturing sector—especially leading automotive accessory manufacturers like Okjaws—has built a global reputation rooted in engineering excellence, precision tooling, and ISO-certified quality systems.

From its industrial evolution in the 1980s to its current strengths in high-mix, low-volume production, Taiwan continues to offer B2B buyers strategic advantages that go far beyond cost. By focusing on material integrity, lean production, and brand customization, Taiwan-made products have earned the trust of OEMs, fleet operators, and e-commerce sellers worldwide.

Through side-by-side comparisons, real-world case studies, and strategic sourcing insights, the article highlights why “Made in Taiwan” is not just a label—but a premium signal of quality, consistency, and global competitiveness. Whether you’re a sourcing manager, distributor, or brand owner, understanding the value behind Taiwan quality is critical to making smarter procurement decisions in 2025 and beyond.

Introduction

In today’s competitive global supply chain, the phrase “Taiwan quality” still carries exceptional weight. Known for precision manufacturing, reliable delivery, and stringent quality control, Taiwanese factories continue to earn the trust of global buyers—from OEMs to high-performance aftermarket brands. While many regions have raced to the bottom on cost, Taiwan has carved out a different path—one built on manufacturing excellence and a reputation for long-term dependability.

This article explores why “Made in Taiwan” remains synonymous with premium, and how respected manufacturers like Okjaws have leveraged their decades of craftsmanship and innovation to build global credibility. For B2B procurement teams, automotive sourcing managers, and international distributors, this is more than just a country of origin—it’s a strategic advantage.

The Origins of Taiwan’s Manufacturing Reputation

Taiwan’s journey from a developing economy to a global manufacturing powerhouse began in earnest during the 1980s and 1990s, when it emerged as a key supplier in sectors such as electronics, bicycles, and precision components. Supported by pro-business government policies, robust infrastructure investment, and a culture that values education and engineering, Taiwan built a reputation for delivering quality products with consistency and efficiency.

A defining factor in this transformation was the development of specialized industrial clusters, particularly in central Taiwan. Regions like Changhua, where Okjaws is based, became synonymous with high-precision metalworking, automotive parts manufacturing, and small-to-medium-sized enterprise innovation. These tightly-knit ecosystems allowed suppliers to collaborate, share technology, and accelerate product development—all while maintaining a commitment to just-in-time production and lean manufacturing principles.

Equally important was Taiwan’s deep investment in its workforce. Skilled labor wasn’t just trained in manual techniques—it was embedded with a mindset of craftsmanship and continuous improvement. As Taiwan manufacturers adopted ISO-certified quality systems and rigorous QC procedures, international buyers began to view “Made in Taiwan” as a seal of trust—a benchmark for reliability, durability, and long-term performance.

In the B2B world, where product failures translate into reputation loss and logistical costs, this reliability was priceless. Over time, Taiwan became the go-to choice for companies seeking partners who could deliver OEM-grade quality at scale, without sacrificing engineering integrity.

Today, that legacy endures. Whether it’s automotive accessories, smart electronics, or precision tools, Taiwan-made still means trusted and durable—a reputation earned through decades of manufacturing discipline.

Defining “Taiwan Quality” in 2025

As global buyers become increasingly discerning, the definition of “Taiwan quality” in 2025 goes far beyond price and punctuality—it represents a benchmark of manufacturing excellence grounded in materials, precision tooling, and uncompromising quality control.

Excellence in Materials and Tooling

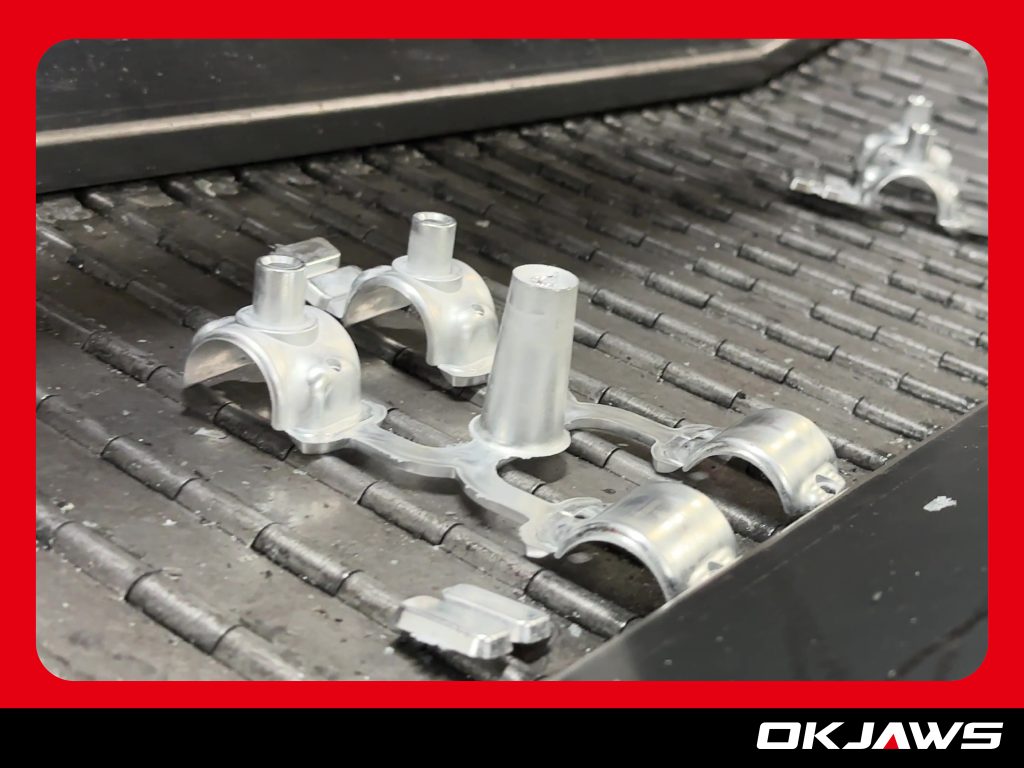

Taiwanese manufacturers, particularly in the automotive accessories sector, continue to outperform global competitors by investing in high-performance materials and refined tooling techniques. Rather than opting for cheap plastic or cost-cutting shortcuts, trusted factories like Okjaws prioritize zinc alloy construction, known for its strength, weight, and corrosion resistance.

This material superiority enables products—such as steering wheel knobs—to deliver a premium tactile experience, long-term structural integrity, and enhanced driver safety. Combined with precision-engineered bearings, these components outperform lower-grade alternatives in durability and ergonomics.

Case Study: Okjaws vs. Mass-Market Alternatives

A prime example lies in the comparison between Okjaws’ zinc alloy steering wheel knobs and common mass-market plastic versions:

- Okjaws:

- CNC-tooled zinc alloy base

- Ball-bearing mechanism with 10,000+ cycle testing

- No-slip secure screw-mount installation

- ISO 9002-compliant production process

- Mass-market plastic knobs:

- Injection-molded plastic casing

- Friction-fit or clip-on mechanisms prone to failure

- No durability testing

- Uncertified or informal factory setup

The result? Fewer returns, higher customer satisfaction, and stronger brand trust—especially critical for OEMs and large-scale distributors.

Taiwan’s Quality Framework: Certifications & Standards

Taiwanese manufacturers reinforce their excellence with globally recognized certifications. Many—including Okjaws—operate under ISO 9002 quality management systems, ensuring:

- Standardized production consistency

- Documentation and traceability for every unit

- Multistage quality control, including material validation, product lifecycle testing, and final inspection

These practices give B2B procurement managers and sourcing specialists the data-backed confidence needed to minimize risk and maintain brand integrity in competitive global markets.

Infographic: Taiwan Quality vs. Global Benchmarks

|

Quality Element |

Taiwanese Manufacturers (e.g., Okjaws) |

Mass-Market Suppliers |

|

Core Material |

Zinc Alloy (automotive-grade) |

ABS Plastic (general purpose) |

|

Tolerance Accuracy |

CNC-milled to ±0.01 mm |

Molded with ±0.2 mm variation |

|

Certification |

ISO 9002 |

Often uncertified |

|

QC Process |

3-phase (materials, assembly, endurance) |

Visual inspection only |

|

Product Lifecycle |

Tested to 6 months under active use |

Degrades within 1-2 months |

|

Brand Impact |

OEM-grade, low return rate |

High risk of product failure |

In an era where global branding and end-user expectations are higher than ever, “Taiwan quality” is not just a label—it’s a competitive strategy. From Okjaws’ advanced tooling and ISO-certified systems to the island’s reputation for precision and reliability, Taiwanese manufacturers continue to deliver the durability, safety, and trustworthiness that premium buyers demand.

Building a Brand with Manufacturing Excellence

In today’s globalized automotive accessories market, it’s no longer enough to simply manufacture a functional product—brands must be built on engineering credibility and proven performance. This is where Taiwanese companies like Okjaws stand apart. They don’t just produce for others—they elevate their identity through a blend of OEM-grade craftsmanship and strategic brand development.

From Factory Floor to Global Brand

With over 40 years of experience, Okjaws has evolved from a contract manufacturer into a globally recognized name in steering wheel accessories. By integrating OEM production capabilities with proprietary design and branding services, the company delivers not just a product—but a complete B2B solution trusted by fleet managers, online retailers, and aftermarket distributors worldwide.

Innovation Starts In-House: R&D at the Core

At the heart of Okjaws’ brand strength is its in-house research and development team. This team continuously refines product ergonomics, material selection, and safety features to meet the evolving needs of global drivers. Whether it’s integrating smoother bearings, enhancing grip texture, or rebalancing weight distribution, the innovation pipeline never stops.

This capability allows Okjaws to respond rapidly to market feedback—offering fast product iteration without compromising quality. For buyers, this means quicker time-to-market and the ability to stay ahead of emerging trends.

Brand Personalization: Custom Logo Support

Brand visibility matters—especially for OEM partners and fleet operations. That’s why Okjaws offers custom logo services that allow clients to embed their brand directly on the product body. Whether it’s a national distributor, a commercial fleet operator, or a regional car gadget brand, this personalized option reinforces end-user trust and builds long-term brand equity on every dashboard.

This level of customization, backed by Taiwan’s manufacturing precision, is a major selling point for B2B clients who want more than off-the-shelf generic goods.

Lean Production Meets Market Agility

Operating under lean production principles, Okjaws maximizes efficiency while minimizing waste. Smaller batch sizes, flexible tooling, and quick changeovers enable shorter lead times and scalable volumes—a perfect match for international buyers looking to test new SKUs or introduce limited-edition products.

With such agile systems, Okjaws supports both high-volume OEM contracts and low-MOQ branded orders, ensuring no opportunity is missed in a rapidly shifting global market.

What Distributors Say

“We’ve had fewer product returns since switching to Okjaws. Their quality is truly consistent, and their ability to offer branded versions for our local campaigns has helped us grow customer loyalty.”

— Automotive Parts Distributor, Europe

“The knobs from Okjaws significantly improved steering comfort for our drivers. The build quality is excellent, and they delivered ahead of schedule.”

— Fleet Manager, Commercial Vehicle Operator

By fusing manufacturing excellence with brand-centric thinking, Okjaws demonstrates how Taiwan-made products can become global category leaders. It’s not just about making parts—it’s about building partnerships, powering brands, and leading with quality.

Global Branding Starts at the Factory

In a world where brand trust determines purchasing decisions and long-term contracts, the factory floor is where brand equity begins. For decades, Taiwan’s manufacturing sector has proven that branding is not just about logos or marketing—it’s about delivering consistent, verifiable quality at scale. And in 2025, this principle is more relevant than ever.

Manufacturing Excellence = Brand Trust

For global buyers, especially in B2B procurement, brand promises must be backed by factory performance. Product quality, lead time, durability, and post-sale consistency are the real foundations of a premium brand. Taiwanese manufacturers, led by companies like Okjaws, understand this intrinsically. Every knob produced in their ISO 9002-certified facility reflects the precision, safety, and reliability that distributors build their own reputations on.

When your customers associate your brand with excellence, they’re often reacting to the manufacturing DNA behind the product. Okjaws proves this by embedding engineering discipline into every product iteration—from material sourcing to final assembly.

Taiwan: From Supplier to Strategic Brand Partner

The outdated notion of Taiwan as a “behind-the-scenes” contract supplier no longer holds. Today’s Taiwan-based companies are proactive brand builders, partnering with international clients to co-create product experiences that reflect mutual values—durability, style, innovation, and trust.

Companies like Okjaws go beyond white-label production. They collaborate closely with B2B clients to refine product designs, implement logo customization, and offer brand-consistent packaging and messaging—turning manufacturing into a strategic brand advantage.

This shift is especially valuable for Amazon sellers, regional distributors, and specialty retailers who need distinctive, premium-positioned products that stand out in saturated markets.

Global Buyers Are Prioritizing Value Over Volume

While cost is always a factor, the modern B2B buyer increasingly weighs total cost of ownership, not just upfront price. Cheap products with high failure rates, inconsistent QC, or reputational risk no longer justify minor savings.

According to global procurement trend reports, buyers are shifting toward trusted production partners who can offer:

- Long-term consistency

- Proven QC systems

- Branding support and customization

- Transparent, responsive communication

In this environment, Taiwan’s manufacturing excellence becomes a competitive moat, not a commodity.

By building products that consistently perform, Taiwan-based manufacturers like Okjaws help their partners build brands that stand for reliability, premium design, and customer satisfaction. In short: global branding doesn’t happen after the product ships—it starts where the product is born.

The Strategic Advantage of Being “Taiwan-Made”

Beyond product quality, global buyers are increasingly evaluating where their products are made—not only for logistics, but for risk mitigation, intellectual property (IP) protection, and long-term reliability. In this context, Taiwan offers strategic advantages that few manufacturing regions can match, making it a smart choice for B2B buyers seeking value beyond price.

Political Stability and Legal Protections

Taiwan stands out in Asia as a politically stable democracy with a transparent legal system and strong enforcement of international trade laws. For B2B clients managing long-term contracts or proprietary product designs, Taiwan’s robust IP protections and enforceable contracts create a sense of security that goes beyond transactional relationships.

Unlike some competing regions, Taiwan maintains strict adherence to international compliance standards, from ISO certifications to ESG reporting protocols. For brands concerned with governance, traceability, and legal recourse, Taiwan is a preferred manufacturing partner.

Taiwan vs. Mainland China vs. Vietnam: A B2B Procurement Lens

|

Evaluation Criteria |

Taiwan |

Mainland China |

Vietnam |

|

IP Protection |

Strong & enforceable |

Weak enforcement |

Developing, limited protection |

|

Political Stability |

High |

Variable (geopolitical tensions) |

Stable but evolving |

|

Quality Control (QC) |

Consistently high (ISO 9002) |

Varies by factory tier |

Improving, but inconsistent |

|

Manufacturing Agility |

High-mix, low-volume capable |

Optimized for mass production |

Focused on apparel/electronics |

|

Skilled Labor |

Engineering-driven |

Broad but aging workforce |

Cost-efficient but less specialized |

|

B2B Readiness |

High (B2B integration, custom services) |

Mature but cost-pressured |

Growing B2B infrastructure |

|

Language/Communication |

High English proficiency |

Varies by tier |

Moderate English support |

|

Sourcing Risk |

Low |

Rising due to tariffs, supply tensions |

Medium (logistics capacity in development) |

This side-by-side view highlights why Taiwan, especially for niche automotive components, remains the preferred region for buyers who value premium quality, customization, and supply chain stability.

Taiwan’s Role in Niche, High-Mix, Low-Volume Manufacturing

Taiwanese manufacturers excel in the high-mix, low-volume (HMLV) model—ideal for clients who need multiple product variations, custom branding, and frequent design updates without sacrificing consistency.

In sectors like automotive accessories, aftermarket components, and specialized hardware, this flexibility is a game-changer. Okjaws, for example, can produce both OEM-standard knobs and limited-edition customized versions with short lead times and tight tolerances—a rare capability in Asia’s manufacturing landscape.

This HMLV strength aligns perfectly with the needs of:

- International distributors managing diverse product lines

- Amazon and e-commerce sellers needing fast customization

- Fleet buyers requiring branded or function-specific variants

For B2B buyers seeking predictable quality, global compliance, and agile production, “Taiwan-Made” isn’t just a label—it’s a strategic advantage in a volatile world.

How B2B Buyers Leverage Taiwan-Made Reputation

As global supply chains grow more complex, B2B buyers—from OEM procurement officers to e-commerce entrepreneurs—are prioritizing predictability, quality, and partnership over pure cost savings. In this environment, Taiwan-based manufacturers have become trusted allies, offering reliability that directly translates into business performance.

Why Global Buyers Choose Taiwan-Based Partners

For OEMs, the need for long-term consistency, engineering support, and global compliance makes Taiwan an ideal sourcing base. Manufacturers like Okjaws offer a rare balance: precision manufacturing paired with flexibility, allowing OEMs to align Taiwan-made components with their own brand standards and production timelines.

For fleet operators, reliability is critical. Products such as steering wheel knobs must endure high-frequency usage in commercial vehicles. The reputation of “Taiwan quality” gives fleet buyers the confidence that equipment will perform over time, minimizing downtime and warranty claims.

For Amazon sellers and e-commerce brands, Taiwan-made products deliver better customer ratings, fewer returns, and stronger reviews. This directly impacts seller rankings, ad ROI, and platform visibility—making sourcing from Taiwan not just a quality decision, but a growth strategy.

The ROI of Consistent Quality

Every product return is more than a logistics headache—it’s a brand reputation loss and a cost center. Taiwan-made goods have proven time and again to reduce that risk. B2B buyers consistently report:

- Lower defect rates due to multi-stage quality control

- Tighter product tolerances due to advanced tooling

- Better customer satisfaction and fewer complaints

Okjaws, for example, combines zinc alloy strength, ball-bearing mechanisms, and ISO 9002-certified processes to produce steering knobs that outlast and outperform mass-market alternatives.

Strategic Sourcing Tip: Vetting a Premium Taiwanese Manufacturer

Choosing the right Taiwan-based partner requires more than a quote comparison. Savvy buyers follow these steps to ensure they’re working with a true quality manufacturer:

- Request tooling and mold details

- High-end manufacturers will offer data on tool lifespan, tolerances, and maintenance schedules.

- Ask for internal QC inspection reports

- Look for documented pass/fail rates, material traceability, and finished product inspection logs.

- Evaluate product sample consistency

- Request multiple units and assess uniformity in weight, surface finish, assembly, and packaging.

- Confirm certifications

- A premium supplier should readily share ISO, RoHS, or other applicable documentation.

- Assess communication transparency

- Strong partners provide clear timelines, contingency plans, and ongoing technical support.

For buyers managing thousands of SKUs or supporting their own brand, these steps ensure alignment with long-term performance and customer satisfaction goals.

Future-Proofing the “Premium” Brand with Innovation

In a fast-changing global market, brand reputation is no longer sustained by legacy alone—it must be constantly earned and renewed through innovation. Taiwanese manufacturers understand this well. To maintain their edge in the next decade, they are proactively investing in smart factories, sustainable practices, and data-driven production systems that align with both buyer expectations and international compliance mandates.

Taiwan’s Transition to Smart and Sustainable Manufacturing

As global demand grows for ethical sourcing and environmentally responsible products, Taiwan has positioned itself as a leader in intelligent manufacturing and green innovation. Leading factories—including those in automotive accessories—are adopting:

- Smart factory technologies such as real-time monitoring, predictive maintenance, and automated quality checks

- Lean production systems integrated with digital feedback loops for faster iteration and reduced waste

- Eco-conscious processes, including energy-efficient tooling, recyclable materials, and waste minimization programs

These developments not only reduce operational costs but also future-proof brand value for buyers who prioritize sustainability and compliance in their supply chains.

Automation and Data-Driven Manufacturing as Brand Differentiators

Taiwanese manufacturers are increasingly using automated assembly lines, CNC-controlled processes, and data analytics to ensure product consistency at scale. By connecting machinery with real-time production data, companies can identify inefficiencies, reduce defect rates, and deliver higher first-pass yield—a critical KPI for global OEMs and B2B distributors.

This commitment to operational transparency and performance analytics enables buyers to trace every unit back to its production lot, ensuring accountability, traceability, and measurable ROI.

Aligning with Global ESG Expectations

As ESG (Environmental, Social, and Governance) criteria become embedded in corporate procurement policies, buyers are demanding more from their suppliers—not just in product performance, but in ethical practices and life cycle transparency.

Taiwanese manufacturers have responded by:

- Conducting Life Cycle Assessments (LCA) to evaluate carbon impact

- Complying with international regulations like REACH, RoHS, and WEEE

- Integrating ESG reporting frameworks to communicate sustainability commitments

- Participating in industry certifications such as ISO 14001 (environmental management)

For global buyers preparing for the 2025–2030 procurement cycle, these capabilities are no longer optional—they are key selection criteria that determine supplier eligibility.

Case Spotlight: How Okjaws Built a Premium Global Reputation

Few companies exemplify the promise of “Taiwan quality” better than Okjaws, a specialist in steering wheel knob manufacturing with a legacy spanning over four decades. From its roots in Changhua’s precision tooling hub to its current partnerships with global distributors and e-commerce leaders, Okjaws has become a textbook example of how Taiwan-made products achieve international premium status.

Four Decades of Engineering Discipline

Founded in 1976, Okjaws has consistently focused on one core product category—steering wheel spinners—and has refined every detail through time-tested methods and modern innovations. With over 40 years of continuous production, the company has accumulated a deep understanding of user ergonomics, material science, and industrial design that few competitors can match.

Each Okjaws product reflects Taiwan’s culture of manufacturing excellence, combining zinc alloy strength, precision bearing technology, and screw-secured safety features into a single, performance-driven component. This focus on durability and safety has enabled the company to earn ISO 9002 certification and maintain long-term relationships with international buyers.

Trusted by Amazon Sellers and Global Distributors

Okjaws has earned a strong reputation among top Amazon sellers and large-scale distributors across Europe, North America, and Asia. These B2B clients choose Okjaws not only for its product quality, but for its:

- Custom branding capabilities (logo engraving, packaging personalization)

- Fast lead times even for small to mid-sized orders

- Consistently low return rates across different sales channels

- Compliance with global standards, making products eligible for markets with strict safety and quality requirements

This unique combination of OEM-level quality and market agility allows Okjaws clients to scale product lines confidently while maintaining strong consumer reviews and low warranty claims.

What Makes Okjaws a Benchmark for Taiwan Premium Branding

Okjaws isn’t just a manufacturer—it’s a strategic partner. The brand has proven that premium status in the global automotive accessory market can be achieved by:

- Staying product-focused: Specializing in one category and perfecting it over time

- Investing in tooling and testing: Precision CNC operations, lifecycle testing, and QC integration

- Supporting B2B branding needs: Custom logos, flexible MOQ, and product exclusivity options

- Operating transparently: Sharing tooling specs, inspection reports, and delivery timelines

- Remaining rooted in Taiwan’s industrial ecosystem: Leveraging the best of local engineering talent and supplier networks

As buyers seek not only functionality but reputational reliability, Okjaws demonstrates how a Taiwan-based company can grow from a manufacturing specialist into a globally respected, brand-strengthening asset. It’s a shining case of how “Made in Taiwan” is not just about origin—it’s about performance, trust, and long-term value.

Conclusion: Why Taiwan-Made Is Still the Smartest Choice for Global Buyers

In an era defined by supply chain volatility, consumer scrutiny, and digital transparency, the label “Made in Taiwan” has evolved into something far more meaningful than a mark of origin—it has become a strategic brand asset. For B2B buyers across industries, Taiwan represents a dependable partner in the pursuit of quality, innovation, and long-term product performance.

This article has explored how Taiwan quality, backed by decades of manufacturing excellence, has empowered global companies to build stronger, more resilient brands. Whether through material superiority, lean production, smart factory investments, or personalized branding support, Taiwanese manufacturers consistently deliver on the promises that modern procurement demands.

Companies like Okjaws have proven that premium branding doesn’t begin with marketing—it begins with engineering discipline, product reliability, and customer-centric production systems. Their success is not an exception, but rather a reflection of what Taiwan’s industrial ecosystem does best: merge precision with agility, and tradition with forward-thinking innovation.

Whether you’re a distributor, fleet buyer, or global OEM—partnering with a Taiwan-made manufacturer like Okjaws means choosing long-term brand value. It means fewer returns, stronger end-user satisfaction, and the confidence that every product leaving the factory reflects the excellence your brand stands for.