Table of Contents

ToggleSix-Step Pad Printing Process

- Logo Design Engraving

- Ink Application

- Ink Pickup by Silicone Pad

- Logo Transfer to Product

- Drying and Setting

- Quality Inspection

Introduction

In today’s competitive market, branding is everything—and one of the most effective ways to customize products is through pad printing. This versatile printing method allows companies to apply logos and designs onto products of all shapes and sizes, even those with curved or uneven surfaces.

Pad printing is widely used across industries because of its precision, efficiency, and ability to handle complex surfaces that other printing methods can’t. Whether it’s a small logo on a car accessory or detailed branding on promotional items, pad printing ensures a clean, professional finish.

In this article, we’ll walk you through how Okjaws uses pad printing to bring your logo to life, and more importantly, how we maintain top-tier quality throughout every step of the process.

What is Pad Printing?

Pad printing is a printing process that transfers ink from an etched plate onto a product using a soft, flexible silicone pad. It’s a popular method for applying logos, designs, and text onto objects that are difficult to print on with traditional methods.

One of the biggest advantages of pad printing is its precision. The soft pad can press ink into small, detailed areas with incredible accuracy. Even better, it can handle curved, textured, or uneven surfaces—making it perfect for printing on things like car accessories, electronics, and promotional items.

Pad printing is also cost-effective, especially for small production runs, and works well on a wide range of materials including plastic, metal, rubber, glass, and more. That’s why it’s a go-to solution for customizing everything from keychains and phone holders to steering wheel knobs and dashboard gadgets.

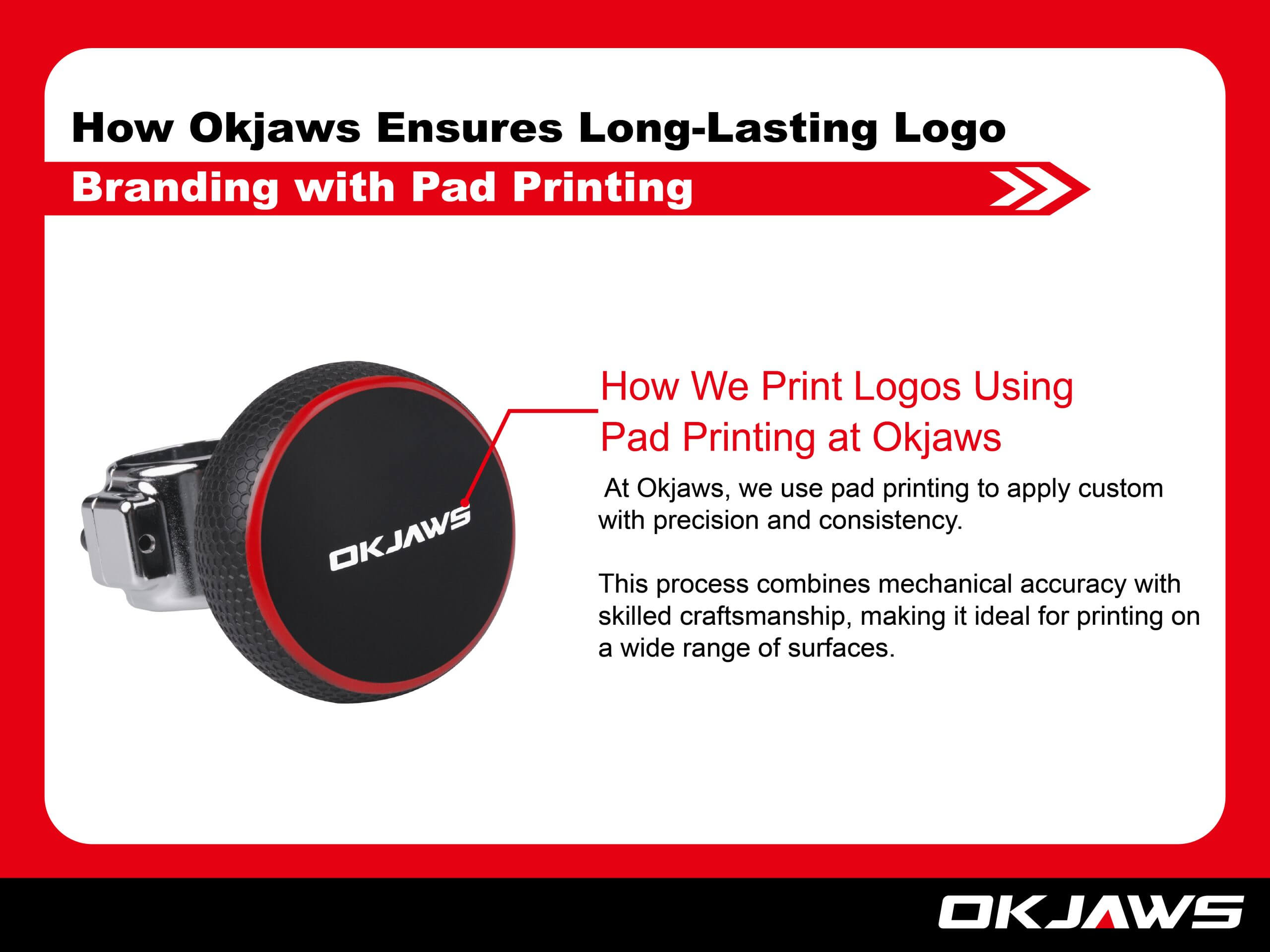

How We Print Logos Using Pad Printing at Okjaws

At Okjaws, we use pad printing to apply custom logos with precision and consistency. This process combines mechanical accuracy with skilled craftsmanship, making it ideal for printing on a wide range of surfaces. Here’s a step-by-step look at how we bring your logo to life:

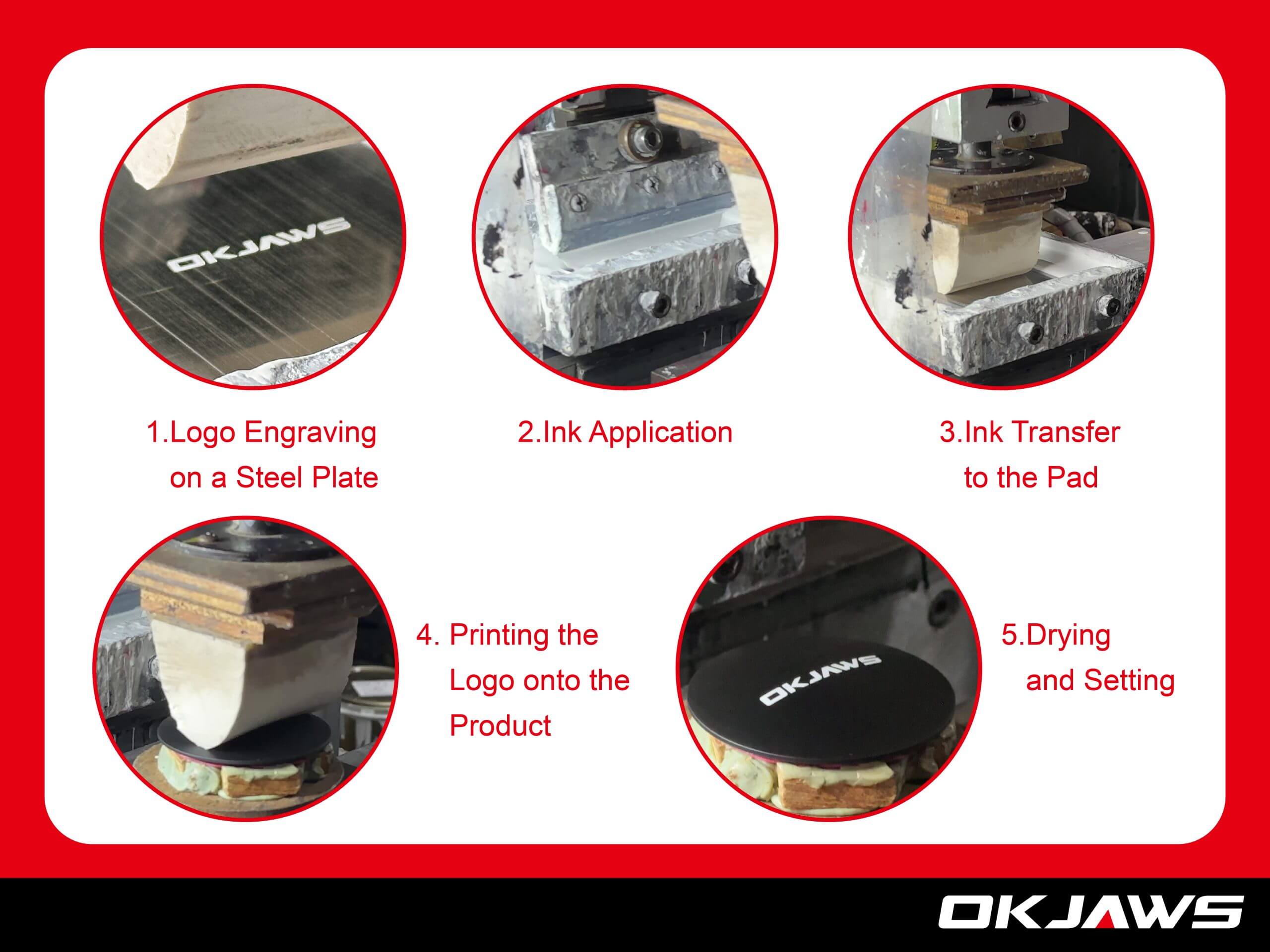

Step 1: Logo Engraving on a Steel Plate

The process begins by engraving the logo design onto a thin steel plate, also known as a cliché. This plate serves as the mold for the print. The engraving is carefully done to capture every detail of the logo, ensuring clarity and accuracy in the final result.

Step 2: Ink Application

Next, ink is spread evenly across the surface of the steel plate. A blade, known as a doctor blade, passes over the plate to remove excess ink, leaving ink only in the engraved areas where the logo was etched.

Step 3: Ink Transfer to the Pad

A soft silicone pad is then pressed onto the steel plate. The pad picks up the ink from the engraved area, effectively “lifting” the logo image. Thanks to its flexibility, the pad can adapt to curved or uneven surfaces, making it ideal for complex product shapes.

Step 4: Printing the Logo onto the Product

The inked pad is carefully aligned and pressed onto the designated area of the product. This action transfers the logo from the pad to the product surface, producing a clean and precise print.

Step 5: Drying and Setting

Finally, the printed product is allowed to dry, either through air drying or using a drying system depending on the type of ink used. This ensures the logo adheres properly and maintains its sharpness and durability over time.

How Okjaws Ensures High-Quality Pad Printing

At Okjaws, printing your logo is only part of the job—making sure it lasts is just as important. Our strict quality control process ensures that every pad-printed logo is sharp, durable, and reliable. Here’s how we maintain top-tier standards from start to finish:

1. Precision Engraving

Quality starts with the mold. We use high-grade steel plates and advanced engraving techniques to ensure each logo is etched with perfect detail and consistency.

2. High-Performance Ink

We carefully select inks that are both vibrant and long-lasting. Each batch is matched to the desired color and tested for adhesion and durability to suit the product’s material and use case.

3. Pad Control and Maintenance

The silicone pad is a key element in the process. We choose the right pad based on product shape and surface type, and we regularly clean and inspect pads to maintain sharp, clean transfers every time.

4. Skilled Printing Operators

Our experienced team oversees each step of the process. They ensure proper alignment, pressure, and print position to prevent misprints, smudges, or uneven application.

5. Adhesion Testing with Tape

To verify the print quality, we use a simple but effective test. A piece of tape is applied firmly over the printed logo and quickly peeled off:

- If the ink lifts or peels, the print is rejected.

- If the logo stays perfectly in place, it passes.

This ensures that the logo is strongly bonded to the surface and won’t flake or fade during everyday use.

6. Ongoing Random Inspections

Throughout the production run, we perform random checks to identify and correct issues early. This helps us maintain consistent quality across all units before packaging and delivery.

Why Choose Okjaws for Pad Printing?

When it comes to pad printing, Okjaws is more than just a manufacturer—we’re your trusted partner in delivering high-quality, customized branding solutions. Here’s why customers choose us again and again:

Expertise and Experience

With years of experience in product customization and logo printing, our team understands the technical details and creative needs involved in every project. We know what works, and we do it well.

Flexibility for Bulk or Custom Orders

Whether you need a large production run or a small batch of custom-branded items, we have the capacity and flexibility to deliver—on time and on target.

Reliable and Professional Results

Our precise process and rigorous quality control ensure that every printed logo is sharp, durable, and professionally finished. Your brand deserves to look its best, and we make sure it does.

Dedicated to Customer Satisfaction

From initial design to final inspection, we work closely with our customers to understand their needs and exceed their expectations. Your satisfaction is at the core of everything we do.

Conclusion

Pad printing is a powerful and versatile method for applying logos with precision, even on complex or uneven surfaces. At Okjaws, we take this technique to the next level by combining expert craftsmanship, high-quality materials, and a strict quality control process to ensure every logo we print is clean, durable, and exactly as you envisioned.

Whether you’re looking to brand a single product line or a wide range of items, we’re ready to help. Get in touch with us to discuss your custom logo printing needs—we’re here to make your branding stand out.

You May Also Want To Know

Inside the Okjaws Steering Wheel Knob: How Bearings Boost Performance

Plastic vs. Zinc Alloy: Choosing the Best Steering Knob Base for Safety and Durability

Revolutionize Your E-Commerce Supply Chain with Okjaws