Table of Contents

ToggleAbstract

-

Introduction to Manufacturing Transparency

Explains why steering knob assembly quality is mission-critical for fleets and OEMs, and how production consistency impacts procurement risk and brand trust. -

Company Background

Profiles OKJAWS’s evolution from a local Taiwanese factory to a globally recognized OEM supplier, with ISO-compliant operations and international distributor networks. -

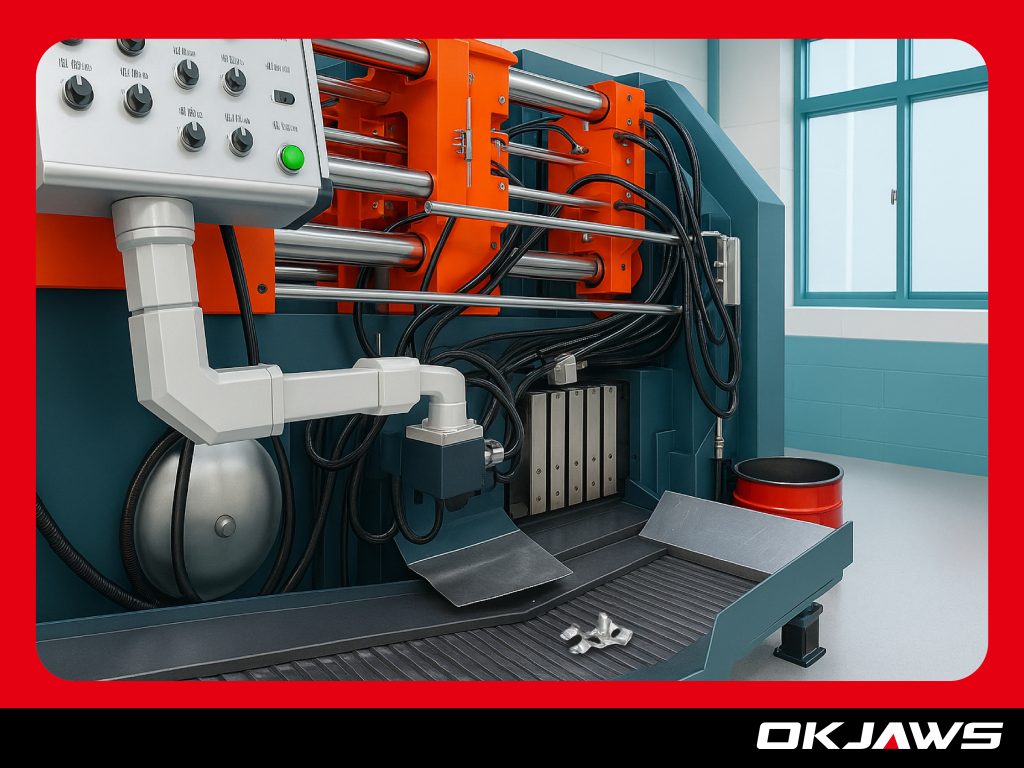

Raw Materials & Component Preparation

Highlights the use of zinc alloy over plastic, batch inspection procedures, and high-pressure die-casting to ensure structural strength and durability. -

Bearing System Integration

Details the integration of precision-sealed ball bearings and QA steps like rotation testing and axial alignment to deliver smooth, frictionless performance. -

Screw-Locking & Anti-Wobble Assembly

Demonstrates OKJAWS’s use of calibrated torque tools and vibration tests to ensure stable installation and zero wobble during real-world operation. -

Logo Printing & Branding Customization

Outlines OEM/private label branding options using pad printing or laser etching, including MOQ requirements and print durability testing. -

Quality Control & Safety Testing

Reviews multi-point QC, thermal cycling, UV resistance, and compliance with FMVSS and ECE automotive standards. -

Final Assembly & Packaging

Shows how lean assembly practices are paired with customizable packaging formats for both bulk B2B and e-commerce fulfillment. -

OEM Delivery Model

Explains how OKJAWS supports global JIT delivery, offers scalable and flexible production, and serves both major automotive brands and small batch buyers. -

Brand Trust Through Process Control

Reinforces that manufacturing transparency, consistent QC, and reduced return rates create a solid foundation for long-term procurement partnerships.

Introduction: Why the Assembly Process Matters

In the world of commercial and fleet vehicles, steering knobs are more than just convenience accessories—they are ergonomic control devices that directly affect driver performance, especially in urban, high-frequency maneuvering environments such as logistics hubs, delivery routes, and industrial fleets. For drivers who spend hours behind the wheel, a well-designed steering knob minimizes wrist strain and enhances vehicle control, particularly during low-speed or repetitive turns.

But behind the smooth operation of each knob lies a complex, multi-stage assembly process—a process that must deliver precision, safety, and consistency at every turn. For B2B buyers, especially those sourcing components for OEM integration or resale under private labels, manufacturing transparency is not just a “nice-to-have”—it’s a key procurement requirement. Buyers today expect clear documentation, traceable QA systems, and standardized production workflows to minimize risk and uphold brand promises.

The manufacturing process of a steering knob must therefore achieve repeatable quality at scale, from material selection and bearing alignment to anti-wobble assembly and logo branding. Without a transparent, standardized assembly line, even the smallest defects—such as off-center fittings, bearing friction, or screw loosening—can lead to product returns, safety issues, or OEM contract penalties.

OEM-level quality assurance is critical. It involves more than random inspections; it demands process engineering, design-for-manufacturing (DFM) compliance, and failure-mode testing. At OKJAWS, the steering knob is engineered not just for individual performance but for production repeatability—ensuring that every unit that rolls off the line meets the same stringent benchmarks demanded by OEM clients.

This article offers a step-by-step walkthrough of how OKJAWS brings its steering knob to life—from raw material processing to final QC and packaging. Along the way, you’ll discover how Taiwan’s manufacturing discipline, paired with decades of automotive accessory expertise, enables OKJAWS to maintain its standing as a trusted OEM partner and global distributor favorite.

Summary: Steering knobs play a vital role in fleet safety and efficiency, and their assembly process must deliver precise, repeatable quality to meet OEM expectations. In an era where B2B buyers demand transparency and assurance, understanding how each knob is built matters more than ever.

Company Background: Inside the World of OKJAWS

Since its founding in 1976, OKJAWS Co., Ltd. has built an enduring reputation as a trusted leader in the design and production of automotive steering wheel knobs. What began as a modest manufacturing facility in Changhua, Taiwan, has evolved into a precision-driven enterprise supplying OEM-quality components to automotive clients across North America, Europe, Asia, and Australia.

Over more than four decades, OKJAWS has refined its assembly line workflows, implemented advanced quality assurance protocols, and developed proprietary processes that ensure every product meets global performance and durability standards. As Taiwan’s automotive supply chain moved up the value curve, OKJAWS kept pace by investing in R&D, automation, and skilled workforce training—a combination that today positions the company as one of the most respected steering knob manufacturers in Asia.

What truly sets OKJAWS apart in the OEM production landscape is its deep commitment to repeatable quality, engineering customization, and brand integrity. The company’s manufacturing facilities follow ISO-standard operating procedures and are equipped with high-precision CNC tools, die-casting machines, automated bearing presses, and digital torque calibrators. These systems allow OKJAWS to handle both large-scale OEM contracts and flexible private label orders with the same level of process discipline.

Beyond its domestic capabilities, OKJAWS maintains strategic partnerships with international distributors, OEM integrators, and fleet suppliers. The brand is known not only for its technical precision, but also for its responsive lead times, custom logo printing services, and strong after-sales support. Whether supplying thousands of knobs per month to a European commercial fleet or working with a Japanese retailer on a private label initiative, OKJAWS brings the same ethos: engineered control, consistent quality, and global trust.

Summary: With a 40+ year legacy rooted in Taiwanese manufacturing excellence, OKJAWS has become a benchmark in the steering knob industry. Its reputation in OEM production is built on precision engineering, ISO-driven assembly lines, and strong global partnerships—making it a trusted supplier to B2B clients worldwide.

Step 1 – Raw Materials & Component Preparation

Every high-performance product starts with the right foundation. For OKJAWS steering knobs, that foundation is a robust and durable zinc alloy base, chosen over lower-cost plastic alternatives for one critical reason: long-term structural integrity. In heavy-use scenarios such as logistics vehicles, delivery trucks, or fleet cars, the constant torque applied to a steering knob exposes the core material to stress and fatigue. Plastic cores—common in budget products—can deform or crack under these conditions. In contrast, zinc alloy provides the ideal balance of hardness, corrosion resistance, and manufacturability, making it the material of choice for OEM-grade steering components.

Zinc Alloy vs. Plastic: Why It Matters

The zinc alloy used in OKJAWS products isn’t just a stronger option—it’s an essential component of their OEM compliance strategy. Zinc’s higher melting point, excellent casting behavior, and tensile strength enable tight-tolerance die-casting that results in consistent, high-precision parts. While plastic knobs might suffice in cost-driven markets, they often fail to meet the longevity, heat tolerance, and impact resistance required by fleet managers and automotive manufacturers.

Material Sourcing and Batch Inspection

The manufacturing journey begins with sourcing certified-grade zinc alloy ingots from reputable suppliers. OKJAWS partners with vetted regional vendors and maintains rigorous batch inspection protocols. Each incoming shipment is verified for:

- Alloy composition using spectrometry

- Impurity thresholds

- Dimensional consistency for casting molds

By performing these pre-production checks, the team eliminates upstream variability and ensures every knob starts with a chemically and mechanically stable base.

Die-Casting, Trimming & Quality Inspection

Once the zinc alloy passes batch inspection, it enters the die-casting stage—a tightly controlled process where molten zinc is injected into precision molds. OKJAWS employs high-pressure die-casting machines that operate at optimal speeds to prevent porosity, shrinkage, or cold shuts—common defects that can compromise part strength.

After casting, each raw knob core undergoes automated trimming to remove excess material (flash) and prepare it for downstream processes. The trimmed pieces are then inspected manually and digitally for:

- Dimensional conformity

- Surface integrity

- Casting completeness

Knobs that do not meet spec are immediately rejected or reprocessed, reinforcing OKJAWS’s commitment to zero-defect manufacturing.

OKJAWS prioritizes structural excellence by using zinc alloy instead of plastic, ensuring greater strength, heat resistance, and reliability in fleet or OEM applications. From certified sourcing to precision die-casting and rigorous pre-assembly inspection, this material-first strategy lays the foundation for durable, high-quality steering knobs.

Step 2 – Bearing System Integration

At the core of every OKJAWS steering knob lies its most critical mechanical element: the precision bearing unit. This component is responsible for the knob’s effortless rotation, delivering the smooth, low-friction movement drivers rely on in demanding steering environments—whether they’re navigating urban delivery routes, reversing trailers, or making rapid turns in a fleet vehicle.

Precision Mechanics for Smooth, Controlled Rotation

OKJAWS integrates a sealed ball bearing system into each knob, engineered to provide 360-degree movement with minimal resistance. Unlike lower-cost alternatives that rely on plastic bushings or loose-fitting pivots, these precision bearings:

- Maintain consistent torque response

- Eliminate the jerky feel caused by surface friction

- Offer enhanced control in tight maneuvering situations

The bearings are sourced from certified vendors and selected for load capacity, temperature tolerance, and anti-corrosion properties—ensuring the steering knob remains functional even after thousands of turning cycles under varying road and climate conditions.

QA: Testing for Smoothness and Alignment

To maintain OEM-grade standards, OKJAWS performs a series of quality control checks specifically focused on bearing integration. Each knob must pass:

- Rotation smoothness testing – ensuring there’s no friction buildup or uneven motion across the bearing’s full range

- Axial alignment inspection – confirming the bearing is perfectly seated and does not cause tilt, wobble, or off-center torque

- Noise testing – checking for grinding, rattling, or vibration that could indicate internal bearing failure

These QA procedures are essential not only for product quality but also for driver safety, as misaligned or underperforming bearings can lead to operational failure, steering distraction, or even injury in high-demand driving contexts.

Summary: The bearing unit is the mechanical core of every OKJAWS steering knob. Through tight-tolerance assembly and rigorous QA checks, each knob delivers smooth, centered, and reliable rotation—ensuring driver control, safety, and long-term performance under OEM production standards.

Step 3 – Screw-Locking & Anti-Wobble Assembly

A steering knob must not only rotate smoothly—it must also remain firmly secured to the steering wheel over thousands of turns, jolts, and vibrations. That’s why the screw-locking system used by OKJAWS is a critical part of the assembly process. This phase ensures each knob is tightly fastened, vibration-resistant, and engineered to withstand real-world driving conditions without becoming loose or wobbly over time.

Precision Locking: The Metal Screw Structure

Unlike many low-cost steering knobs that rely on plastic snap-fit mechanisms or glue-based bonding, OKJAWS utilizes a metal locking screw system as part of its anti-loosening architecture. This system includes:

- Reinforced metal brackets that clasp the steering wheel rim securely

- Threaded steel bolts for structural stability

- Non-slip rubber or EVA padding to protect the wheel surface and absorb micro-movements

This design not only provides superior clamping force but also minimizes micro-shifts that can cause product degradation or steering interference over time.

Torque Calibration: Assembly Line Precision

In the OKJAWS assembly line, each screw-locking unit is installed using digitally calibrated torque tools. These tools are set to deliver optimal fastening pressure—tight enough to prevent slippage, but not so tight as to damage the wheel or internal components.

Operators are trained to follow strict torque specifications based on the steering knob model and vehicle compatibility. This practice:

- Prevents overtightening, which can stress materials or deform the knob structure

- Ensures uniform installation across every unit

- Meets OEM expectations for repeatable fastening accuracy

Durability Testing: Simulating Daily Driving Stress

Before packaging, all units undergo vibration and stress testing that simulates the conditions of daily use:

- Repetitive turning simulation – mimics thousands of steering motions in various directions

- Vibration exposure – recreates the effect of driving over rough or uneven terrain

- Thermal cycling – subjects the knobs to heat and cold to detect material expansion or screw loosening

Any unit that fails to maintain structural integrity during these tests is immediately rejected, ensuring that only fully secure and stable knobs make it to the market.

Summary: OKJAWS’s screw-locking assembly process delivers long-term structural reliability by combining reinforced metal brackets, calibrated torque application, and rigorous vibration testing. This ensures each steering knob remains securely in place under real-world driving conditions—making it a trusted choice for OEMs and fleet buyers who value durability and safety.

Step 4 – Logo Printing & Branding Customization

For many B2B buyers, a steering knob isn’t just a functional component—it’s also a brand touchpoint. Whether it’s a fleet operator reinforcing corporate identity, or an OEM enhancing product exclusivity, the ability to apply a custom logo to each steering knob is a valuable differentiator. At OKJAWS, this branding capability is built directly into the production process, allowing clients to personalize without compromising on quality or delivery timelines.

Pad Printing & Laser Etching: Two Professional Methods

To meet the diverse needs of branding-conscious clients, OKJAWS offers two precision-based techniques for logo application:

- Pad Printing (Silicone Transfer)

Ideal for most volume clients, this process uses a silicone pad to transfer ink onto the knob surface. It’s widely used for:- Multicolor or detailed logos

- Fast production at scale

- Uniform placement accuracy across batches

- Laser Etching

Suitable for clients requiring permanent, abrasion-resistant marking, this method uses high-precision lasers to engrave the logo directly into the metal or painted surface. It is:- Resistant to fading, solvents, and wear

- Ideal for industrial or fleet applications

- Preferred when logo durability under heavy use is a priority

Both methods are calibrated into the assembly line, ensuring that branding occurs without disrupting efficiency or unit consistency.

Brand Integration for OEM Clients

OEM clients benefit from the ability to incorporate their company name, model number, or private label identity directly onto OKJAWS knobs. This flexibility allows for:

- Seamless product integration into branded vehicle interiors

- Consistent presentation across distribution and retail networks

- Enhanced recall and brand perception in end-user environments

Because OKJAWS owns the tooling and printing process in-house, lead times are tightly controlled and quality is monitored at every step.

Minimum Order Quantity (MOQ) and Print Durability

For custom logo applications, OKJAWS typically requires a MOQ of 500–1000 units, depending on the complexity of the design and printing method. This ensures cost-efficiency while maintaining the flexibility needed for pilot projects, fleet trials, or regional brand rollouts.

In terms of durability, printed logos are:

- Scratch-resistant, tested through abrasion simulations

- Resistant to UV exposure, heat, and cleaning solvents

- Backed by QA inspection to ensure placement, clarity, and adhesion

Summary: OKJAWS enables OEM and private label clients to reinforce brand identity by offering precision logo customization via pad printing or laser etching. These in-house services are integrated directly into the manufacturing line, ensuring high durability and production efficiency even for moderate MOQs—making OKJAWS a strategic partner for brand-focused automotive buyers.

Step 5 – Quality Control (QC) and Safety Testing

In the automotive supply chain, quality assurance is not optional—it’s mission-critical. Especially for steering-related components, even the slightest inconsistency in size, fit, or function can lead to product failures, user dissatisfaction, or—at worst—safety risks. This is why OKJAWS integrates a multi-tiered Quality Control (QC) system directly into its assembly line, supported by international safety compliance and real-world simulation testing.

Multi-Point QC at Every Stage of the Line

OKJAWS adopts a layered quality assurance model, performing checks at key points during and after assembly to ensure that every knob meets exacting standards. This includes:

- Dimensional Checks:

Using digital calipers and 3D measurement tools, technicians verify that key dimensions—diameter, mounting bracket width, and handle curvature—fall within ±0.1 mm tolerances. - Rotation Testing:

Each unit undergoes a manual spin test to detect any roughness, drag, or bearing irregularities. Units that do not rotate freely under nominal force are rejected. - Wobble Testing:

Special gauges are used to detect vertical or horizontal play. If the knob exhibits even slight lateral movement after screw installation, it is flagged for disassembly or scrap.

These checks are embedded within the lean assembly workflow, ensuring they are performed without introducing production delays or compromising throughput.

Environmental Stress Testing: Built for the Real World

Beyond physical performance, OKJAWS knobs are subjected to environmental durability simulations to ensure their reliability in diverse driving conditions. These tests include:

- Thermal Cycling – Components are tested between −30°C and +85°C to simulate extreme seasonal variations in cabin temperature. This ensures material expansion/contraction does not affect structural integrity.

- UV Stability – Knob surfaces and printed logos are exposed to UV radiation tests simulating long-term sunlight exposure to verify fade resistance and surface resilience.

These tests validate that OKJAWS products can withstand years of use in global fleet environments, from humid tropical cities to sun-exposed parking lots and cold-weather regions.

International Standard Compliance: FMVSS and ECE

To meet the procurement criteria of OEMs and Tier 1 distributors, OKJAWS engineers its steering knobs in compliance with global automotive safety standards, including:

- FMVSS (Federal Motor Vehicle Safety Standards – USA)

- ECE Regulations (Economic Commission for Europe – UN)

While steering knobs are often considered accessory components, adherence to design principles and mechanical integrity requirements found in these standards helps OKJAWS build trust with OEM clients who demand a total quality manufacturing approach.

Summary: Through dimensional precision, mechanical testing, and rigorous environmental stress validation, OKJAWS ensures every unit meets and exceeds OEM buyer expectations. With built-in compliance to FMVSS and ECE standards, the company’s QC program delivers a product that’s not only functional and durable—but globally trusted for safety and performance.

Step 6 – Final Assembly & Packaging

The final stage of the OKJAWS manufacturing process is where precision engineering meets operational efficiency. Once each steering knob has passed all quality control checkpoints, it moves into final assembly and packaging—a phase designed not only to preserve product integrity during global transit, but also to support branding, traceability, and channel-specific needs across diverse B2B customer profiles.

Lean Assembly Line Workflow

OKJAWS adopts a lean manufacturing model, reducing waste while ensuring consistency across high-volume production runs. At this stage, all components—including the knob head, bracket, bearing unit, and mounting screws—are reverified and assembled using standardized jigs and fixtures. This ensures:

- Perfect part fitment

- Uniform tension across fastening points

- Smooth handling transitions from workbench to packing line

This workflow is engineered for scalability, capable of supporting both large OEM contracts and private-label production runs with short lead times.

Packaging Customization: B2B Bulk vs. E-Commerce Ready

Recognizing the differing needs of its clients, OKJAWS offers flexible packaging formats tailored for two main distribution paths:

- Bulk B2B Packaging – For fleet operators, wholesalers, and auto parts distributors:

- Multi-unit cartons

- Foam or molded trays for transport protection

- Simplified branding or barcode-only labeling for warehouse stocking

- E-Commerce Packaging – For clients selling via Amazon, Rakuten, or online storefronts:

- Single-unit retail boxes with full-color branding

- Instruction manuals, QR codes, and promotional inserts

- Tamper-evident seals and protective film wrapping

Both packaging types are optimized for stackability, protection, and visual clarity, ensuring products arrive in showroom condition regardless of channel.

SKU Labeling, Barcode Tracking & Packing Standards

Every finished unit receives a SKU identifier and barcode label, aligned with the client’s warehouse or ERP system. OKJAWS supports:

- EAN, UPC, or custom barcode generation

- Lot tracking for traceability

- Serialized packaging for high-value orders

Summary: The final stage of production at OKJAWS combines lean assembly line practices with customizable packaging and barcode tracking systems. Whether for e-commerce, fleet procurement, or OEM bulk supply, this step ensures product safety, branding consistency, and supply chain efficiency—completing a manufacturing process built on precision from start to finish.

From Factory to Fleet: OKJAWS and the OEM Production Model

In today’s automotive supply chain, success isn’t just about building a great product—it’s about delivering the right product, at the right time, with the right flexibility. OEM partners and fleet procurement teams operate on tight timelines, evolving specs, and regional rollout plans that demand more than just manufacturing capability—they require an ecosystem of supply chain precision and production agility. OKJAWS was built for exactly that.

Just-in-Time (JIT) Delivery for OEM and Tier 1 Partners

OKJAWS integrates JIT delivery systems that sync with OEM production schedules and distributor timelines. For clients operating global assembly lines or multi-site warehouses, this means:

- On-time container loading for regional distribution

- Staggered production lots to align with vehicle build cycles

- Responsive reordering systems for forecast-based replenishment

With accurate lead time controls and reliable shipping workflows, OEM clients reduce inventory holding costs without risking shortages—an essential advantage in lean manufacturing environments.

Global Experience with Fleet Operators and Distributors

Over four decades, OKJAWS has developed strong relationships with:

- Commercial fleet operators managing large vehicle networks

- Aftermarket distributors across North America, Europe, and Asia

- Retail channels including private-label e-commerce and automotive resellers

The company understands the unique needs of these segments—from regulatory compliance and branding flexibility to multi-model compatibility and technical documentation support.

This experience enables OKJAWS to serve a wide range of buyers with tailored solutions, whether it’s a public transportation authority ordering 10,000 knobs or a new distributor testing an initial 500-unit SKU rollout.

Flexible Production: Scalable, Yet Agile

OKJAWS’s vertically integrated factory structure allows for mass production scaling while retaining the flexibility to pivot quickly to smaller batches or custom configurations. Key capabilities include:

- Dedicated tooling stations for fast model switching

- Short lead time prototyping for R&D or pilot runs

- Batch-specific packaging, labeling, and documentation

This hybrid model of scale and flexibility is ideal for:

- OEM clients launching limited-edition vehicle models

- Startups testing regional product-market fit

- Distributors managing multi-brand portfolios

Whether a client needs 50,000 knobs for global supply or 1,000 custom-logo units for a seasonal campaign, OKJAWS can deliver with equal efficiency.

Summary: OKJAWS supports global OEM and fleet clients with a production model that blends mass manufacturing scale and agile customization. With JIT delivery, real-world distributor experience, and flexible batch handling, the company proves it can serve both large automotive brands and fast-moving commercial buyers across diverse markets.

Why It Matters: Manufacturing Quality = Brand Trust

In the competitive world of B2B procurement, especially within the automotive sector, brand trust is built not just on product performance—but on manufacturing consistency and transparency. OEMs, fleet buyers, and global distributors need more than a sample—they need assurance that every unit will meet the same high standard as the first. This is where OKJAWS stands apart: by embedding quality control into every phase of the assembly line, it delivers more than a product—it delivers predictable reliability and buyer confidence.

Process Control Builds Trust, Not Just Output

OKJAWS’s manufacturing model is not a black box. Each process—from die-casting and bearing alignment to packaging and shipment—is governed by a transparent, documentable, and repeatable system. This kind of process visibility allows:

- OEMs to integrate OKJAWS parts into ISO

- Fleet operators to make long-term sourcing decisions based on proven consistency

- Retailers and e-commerce partners to offer warranty-backed products with reduced return risk

For buyers managing volume contracts, regional SKUs, or brand reputations, this level of control is not just helpful—it’s essential.

What Buyers Are Saying

Clients from around the world recognize the difference. For example:

“The knobs from OKJAWS significantly improved steering comfort for our drivers. The build quality is excellent, and we’ve had zero slippage issues since switching.”

— Fleet Operations Manager, Southeast Asia

“With OKJAWS, what impressed us most was the consistency across batches. Even under tight lead times, the quality held up—and our return rate dropped by nearly 70%.”

— Senior Buyer, Automotive Parts Distributor, Europe

These testimonials reflect not just satisfaction with the product, but with the manufacturing process behind the product—the part most B2B customers rarely get to see but always depend on.

The Warranty-Quality Connection

Product quality isn’t just about how something feels in-hand—it’s directly tied to post-sale performance metrics like:

- Return rates

- Warranty claims

- Support tickets

By using durable materials, precision assembly, and stress-tested locking mechanisms, OKJAWS significantly reduces the chance of failures in the field. This in turn lowers warranty costs and boosts buyer margins, especially for fleet operators or resellers managing large customer bases.

Summary: Trust in automotive procurement is earned through manufacturing transparency, consistency, and control. OKJAWS’s rigorous processes, proven testimonials, and real-world quality performance make it a reliable partner for B2B buyers who understand that precision production directly translates into brand trust, reduced warranty risk, and long-term customer satisfaction.

Conclusion: The OKJAWS Manufacturing Promise

Behind every OKJAWS steering knob lies a meticulously engineered process built for precision, durability, and OEM-level trust. From the selection of zinc alloy raw materials to the bearing integration, anti-wobble assembly, branding customization, and rigorous quality testing, each step in the assembly line reflects a company-wide commitment to manufacturing excellence. Every stage is designed to ensure repeatability, enhance user safety, and uphold the brand integrity of our partners.

Let’s recap the core stages that define the OKJAWS production model:

- Raw Materials & Component Preparation – High-grade zinc alloy and tightly controlled casting for structural reliability

- Bearing System Integration – Smooth, frictionless operation via precision ball bearings and manual calibration

- Screw-Locking & Anti-Wobble Assembly – Secure fastening systems and torque calibration for field stability

- Logo Printing & Branding Customization – OEM and private label identity integration through pad printing or laser etching

- Quality Control & Safety Testing – Dimensional checks, stress simulation, and compliance with FMVSS and ECE regulations

- Final Assembly & Packaging – Lean workflow and customizable packaging for both bulk distribution and e-commerce channels

These are not just production stages—they are quality checkpoints, each reinforcing OKJAWS’s standing as a trusted supplier in the global automotive parts ecosystem.

For OEM inquiries, sample requests, or B2B partnerships, we invite you to take the next step:

🔗 Visit Our Company Profile

🔗 Contact Our Sales Team

🔗 Explore Our Product Catalog

Whether you’re sourcing parts for a vehicle line, outfitting a regional fleet, or building your own brand of steering accessories, OKJAWS is ready to deliver with process transparency, supply chain efficiency, and uncompromising quality.

Summary: OKJAWS is more than a steering knob supplier—it’s a precision manufacturing partner trusted by OEMs, fleet operators, and global distributors. With a proven production model and full-spectrum quality control, we help you reduce risk, elevate your brand, and deliver performance that lasts.