About OK JAWS

Our Pad Printing Process : Ensuring Sharp , Durable Logos on Every Okjaws Product

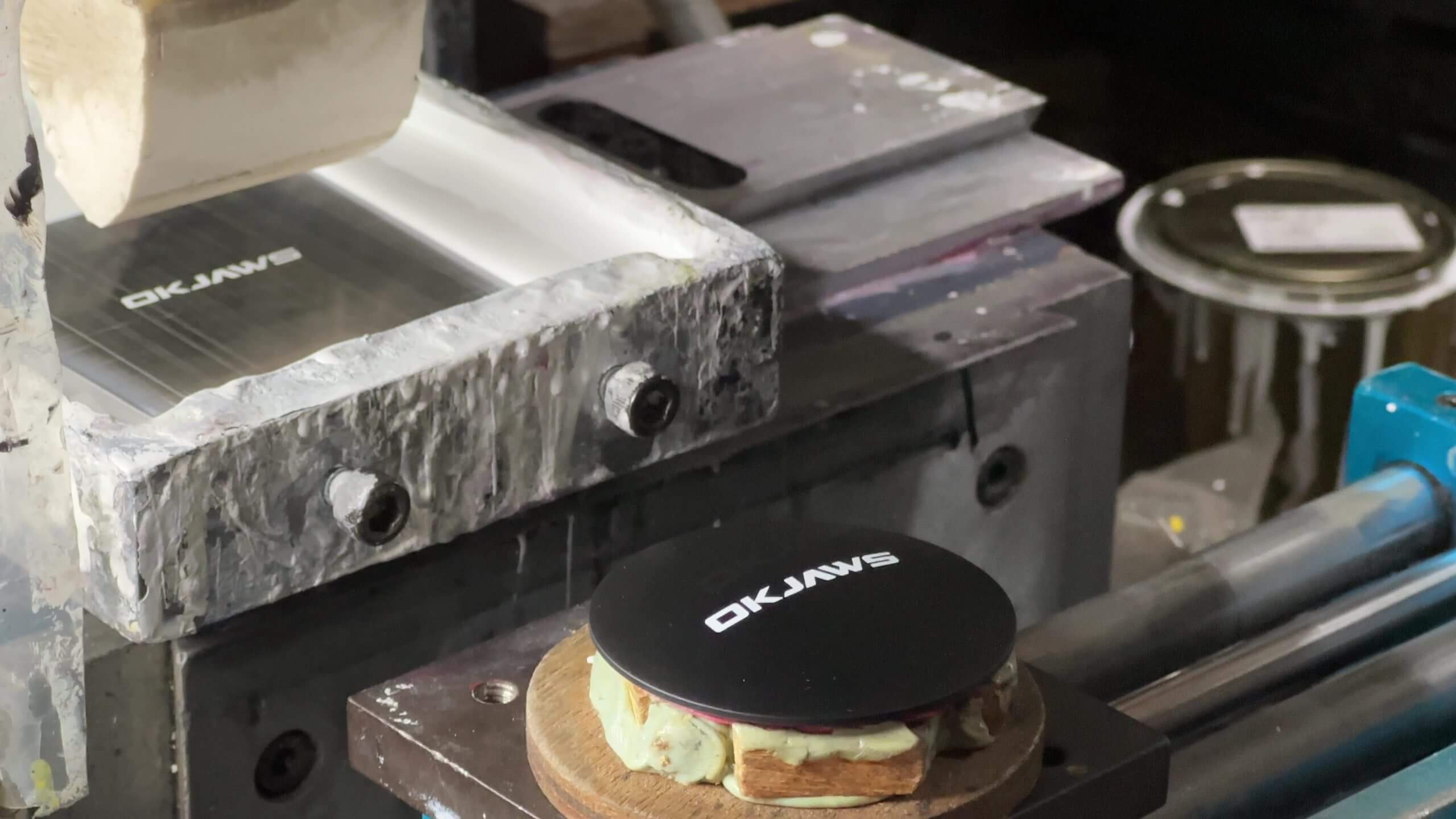

At Okjaws, we use a high-precision pad printing process to apply custom logos to our products with clean, accurate results. This technique is ideal for printing on curved, uneven, or hard-to-reach surfaces—making it perfect for complex shapes like car steering wheel knobs. It enables us to deliver sharp, long-lasting branding across a wide range of materials, including plastic, rubber, and metal.

The process begins by engraving the logo onto a thin steel plate, known as a cliché, which holds ink only in the etched areas. A soft silicone pad presses onto the plate to pick up the ink, then transfers the logo onto the product. The pad’s flexibility allows it to conform to complex surfaces, ensuring precise logo placement without distortion or smudging.

To ensure every logo meets our standards, quality control is built into every step. Our experienced operators monitor the process closely, while printed products undergo a tape adhesion test—tape is applied to the logo and peeled off to check ink durability. If any ink lifts, the product is rejected. We also carry out random spot checks throughout production to catch inconsistencies early. This combination of skilled handling and strict testing ensures each logo is as durable and professional as the product it represents.

Why Choose Us

3 Key Steps

Step 1

Logo Plate Preparation

Step 2

Ink Transfer with Silicone Pad

Step 3

Drying and Quality Inspection

Join The Success

See how our solution can work for your team.

Schedule a free consultation with our team and let’s make things happen!