Table of Contents

ToggleIntroduction: The Enduring Power of “Made in Taiwan”

In the global manufacturing landscape, the phrase “Made in Taiwan” once stood primarily for cost-efficiency and dependable OEM mass production. Today, however, it carries a different—and far more prestigious—connotation. For discerning B2B buyers, product managers, and international sourcing directors, Taiwan-made no longer just implies affordability; it signals precision engineering, long-term reliability, and design-driven excellence.

Taiwan’s manufacturing legacy dates back to the 1970s and 1980s, when it emerged as a vital link in the electronics and components supply chain. Over time, Taiwanese manufacturers began investing in R&D, process automation, and international standards compliance. Rather than competing solely on price like many of their regional peers, Taiwan shifted toward a model of value creation, emphasizing craftsmanship, IP protection, and brand integrity.

Today, sectors such as automotive accessories, semiconductors, medical devices, and smart machinery are proof points of this transformation. Brands like TSMC (semiconductors), Giant (bicycles), and niche manufacturers like Okjaws (automotive steering knobs) showcase the island’s ability to deliver world-class manufacturing paired with agile design and global branding sensibilities. For importers, distributors, and corporate buyers seeking quality without compromise, Taiwan remains one of the most trusted production origins in Asia.

This article explores the three pillars behind Taiwan’s enduring manufacturing prestige:

- Taiwan Quality: rooted in stringent QC, reliable materials, and skilled labor.

- Manufacturing Excellence: supported by ISO/IATF certifications, advanced production systems, and an engineering-first mindset.

- Global Branding: where Taiwan-based OEMs and private-label suppliers now actively build and protect brand equity on the world stage.

Summary: Taiwan has successfully evolved from a cost-focused manufacturing hub into a globally recognized standard-bearer for quality, innovation, and brand trust. This article examines how “Made in Taiwan” remains a premium mark for global buyers through the lens of quality, engineering leadership, and international brand strategy.

The Origins of Taiwan Quality

Taiwan’s ascent in global manufacturing began in the post-1970s industrial boom, initially fueled by OEM contracts from Japan, the U.S., and Europe. In those early decades, Taiwan was known for delivering consistent, cost-effective products in industries such as textiles, plastics, and electronics. But as global competition intensified and mainland China emerged as a dominant low-cost producer, Taiwan made a deliberate pivot—from mass production to value-added, quality-centric manufacturing.

This strategic evolution was anchored in three key areas: investment in engineering talent, commitment to international standards, and early adoption of precision manufacturing technologies. Government-supported initiatives like the Hsinchu Science Park (founded in 1980) catalyzed Taiwan’s transformation into a high-tech economy. It was here that the world began to see what would become one of Taiwan’s greatest industrial symbols: TSMC (Taiwan Semiconductor Manufacturing Company)—now the world’s largest and most advanced chipmaker.

TSMC is more than a semiconductor titan; it’s a case study in Taiwan quality as a competitive asset. With over 90% global market share in advanced chips below 10 nanometers, TSMC exemplifies how process discipline, supply chain transparency, and relentless innovation can propel a Taiwanese manufacturer into the global spotlight. Its production capabilities are defined by atomic-level tolerances, zero-defect targets, and proprietary manufacturing workflows—hallmarks of what “Taiwan quality” truly means today.

But excellence isn’t confined to semiconductors. Taiwan’s bicycle industry is another sector that has led with quality. Giant Bicycles, the world’s largest bike manufacturer, was among the first to adopt carbon fiber frame engineering at scale, blending sports science with precision fabrication. Similarly, in the automotive accessories sector, companies like Okjaws have become known for precision-made components—such as zinc alloy steering knobs with embedded bearings and ISO-certified production lines—delivering quality that satisfies both consumer brands and OEMs.

So why does “Made in Taiwan” still command premium perception in global procurement circles? It’s because Taiwanese manufacturers offer:

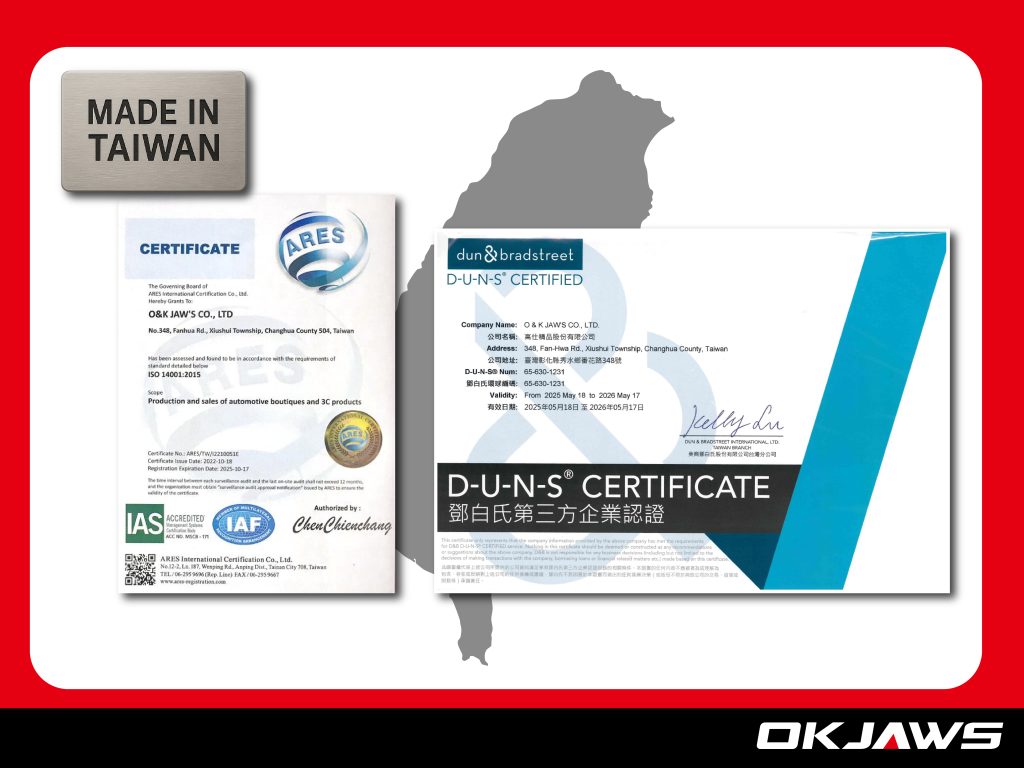

- Consistent quality assurance backed by ISO, IATF, and CE certifications.

- Supply chain stability with a focus on long-term business relationships rather than transactional price wars.

- Agility and customization that meets the evolving needs of OEMs, fleet operators, and premium brand distributors.

In a procurement world where time-to-market, defect rates, and supplier reliability can make or break a brand’s reputation, sourcing from Taiwan offers peace of mind. The manufacturing culture here is not just about meeting specs—it’s about exceeding expectations with a proactive approach to problem-solving, innovation, and continuous improvement.

Summary: Taiwan’s industrial journey from low-cost supplier to a benchmark for global quality is rooted in its dedication to precision, engineering investment, and long-term reliability. From semiconductors to automotive parts, “Taiwan quality” has become a trusted standard for global buyers seeking consistent manufacturing excellence and brand safety.

Engineering Excellence: How Taiwan Delivers World-Class Manufacturing

Taiwan’s position as a global benchmark for manufacturing excellence is not accidental—it is the result of decades of investment in automation, precision engineering, and quality-driven processes. In today’s global sourcing environment, where procurement teams are under pressure to find reliable partners that combine innovation with cost-effectiveness, Taiwan delivers an unmatched formula.

At the core of Taiwan’s production ecosystem lies a mastery of advanced manufacturing technologies, including:

- CNC machining for ultra-precise tolerances across automotive, aerospace, and medical applications.

- High-pressure die-casting—particularly in zinc and aluminum alloys—for structurally critical components.

- Robotic assembly lines to improve repeatability, safety, and operational efficiency.

- Smart factory systems that incorporate AI, IoT sensors, and cloud-based ERP for real-time quality monitoring and lean production.

These capabilities are reinforced by a culture of certification and standardization. Many Taiwanese factories adhere to international benchmarks such as:

- ISO 9001 for quality management systems.

- IATF 16949, the automotive sector-specific standard for OEM and Tier 1 suppliers.

- CE, RoHS, and REACH compliance for export into the EU and North America.

These certifications aren’t just paperwork—they reflect deep operational discipline and risk mitigation practices that procurement officers trust.

A shining example of this ethos in practice is Okjaws, a leading Taiwanese manufacturer of steering wheel knobs. Founded in 1976 and headquartered in Changhua, Okjaws represents the very definition of precision meets durability. Their product lineup features:

- Zinc alloy die-cast bases for superior strength over conventional plastic parts.

- Precision bearing systems that ensure smooth 360° rotation without wobble.

- Screw-lock structures that enhance installation stability and eliminate slippage over time.

- An in-house R&D and tooling division, enabling rapid prototyping and efficient customization for global clients.

Unlike many factories that rely on third-party mold makers or import raw materials of uncertain origin, Okjaws practices vertical integration—controlling the entire value chain from design to packaging. This approach significantly reduces lead time variability, enhances confidentiality in OEM projects, and ensures that branding elements (such as pad-printed logos or packaging) meet global presentation standards.

Additionally, Taiwan’s factories invest heavily in R&D and process optimization, ensuring that they don’t just match global trends—they anticipate and shape them. For example, many automotive accessory makers in Taiwan are already integrating smart features (e.g., sensors, app interfaces) into traditionally mechanical components. The ability to combine mechanical engineering with electronics and software is becoming a signature of Taiwan’s next-generation manufacturing identity.

Summary: Taiwan’s manufacturing excellence is powered by automation, certification, and a relentless commitment to innovation. With factories like Okjaws leading by example, Taiwan proves that world-class production isn’t just about machinery—it’s about materials, standards, integration, and the pursuit of perfection at every step.

Benchmarking Against Global Competitors: Why Buyers Still Choose Taiwan

In today’s hyper-competitive global sourcing environment, procurement professionals often face a difficult balancing act between cost, quality, and supply chain reliability. While many developing economies like China, Vietnam, and India offer attractive pricing, seasoned B2B buyers increasingly look beyond sticker prices. What they value more is total lifecycle performance, predictable quality, and brand safety—areas where Taiwan consistently outperforms.

Taiwan vs. China: Quality Over Quantity

China remains a dominant manufacturing force thanks to scale and infrastructure. However, Taiwanese suppliers offer a markedly different value proposition. Unlike many Chinese factories that focus on high-volume, cost-sensitive production, Taiwanese manufacturers emphasize craftsmanship, tighter QC standards, and export compliance.

More importantly, IP protection remains a significant differentiator. Taiwan has strong intellectual property laws and enforcement practices, offering international brands better security over tooling, product designs, and proprietary technologies. In contrast, IP leakage remains a top concern among foreign firms working with Chinese OEMs, particularly in categories like automotive, electronics, and wearables.

Taiwan vs. Vietnam: Experience and Engineering Depth

Vietnam has become a popular “China Plus One” sourcing destination due to its low labor costs. However, its industrial maturity, engineering talent pool, and vertical integration capacity still lag behind Taiwan. For highly engineered products like precision automotive components, B2B buyers often find Vietnam’s factories limited to basic assembly or plastic injection work, with weaker support for customization or advanced testing protocols.

By contrast, Taiwan offers decades of accumulated domain knowledge, robust engineering universities, and a supplier ecosystem optimized for complex B2B needs—be it for steering wheel knobs, electronics enclosures, or mechanical sub-assemblies.

Taiwan vs. South Korea: Accessible Quality at Scale

South Korea also enjoys a strong manufacturing reputation, particularly in consumer electronics and automotive. However, Korean manufacturing tends to be more centralized among large conglomerates, making it less accessible for small and mid-sized B2B buyers. Taiwan, on the other hand, has an extensive network of mid-sized, agile factories like Okjaws, which combine engineering excellence with flexible MOQ and responsive customer service.

The Hidden Costs of Low-Cost Alternatives

Buyers attracted by lower unit costs often face higher long-term expenses due to:

- Higher defect rates

- Inconsistent quality between production runs

- Delayed shipments due to weak supply chain systems

- Reputational damage from warranty claims or product failures

In sectors such as automotive accessories, where consumer safety, brand image, and repeat sales matter, cutting corners on sourcing can backfire. By working with Taiwanese suppliers who emphasize precision, materials traceability, and continuous improvement, brands safeguard their reputation and reduce post-sale risks.

Taiwan as the Strategic Choice for Brand-Focused Buyers

What sets Taiwan apart is its ability to serve not just as a factory—but as a long-term partner in your brand’s global growth. Whether you’re sourcing under your own label, managing an OEM program, or customizing products for regional markets, Taiwan’s manufacturers offer:

- Durability you can promise to your end customers

- Design confidentiality that protects your brand identity

- Communication fluency that speeds up product development cycles

For example, Okjaws supports global partners with rapid prototyping, branded packaging, and multilingual documentation—capabilities that go beyond manufacturing and into full-service support.

Summary: Compared to lower-cost rivals, Taiwanese manufacturers consistently deliver superior long-term value. Their focus on IP protection, engineering excellence, and brand partnership makes Taiwan the sourcing base of choice for B2B buyers who prioritize reliability, durability, and performance over short-term savings.

Taiwan’s Branding Shift: From OEM to Global Brand Architects

For decades, Taiwan’s economic engine was driven by OEM and ODM manufacturing, producing high-quality goods behind the scenes for major international brands. However, a quiet but powerful transformation has taken root over the past 15 years. Taiwanese companies are no longer content with staying invisible. They are now actively building consumer-facing, globally trusted brands—leveraging their manufacturing backbone to become brand architects, not just suppliers.

The Rise of Taiwan-Born Global Brands

Several Taiwanese companies have already achieved global brand status:

- Giant Bicycles, originally an OEM for major bike brands, is now a global leader with its own powerful identity, known for quality engineering and innovation in cycling.

- ASUS and Acer began as component assemblers and evolved into globally respected consumer electronics brands, competing head-to-head with Western and Japanese tech giants.

- Okjaws, a specialty manufacturer in the automotive accessories space, has carved out a name for itself by blending OEM precision with distinct branding. Known for their steering wheel knobs, Okjaws now serves not only under white-label arrangements but also partners with distributors who want a product that embodies premium, Taiwan-made performance.

These success stories highlight a common strategy: starting with deep technical and manufacturing credibility, then scaling up through storytelling, brand clarity, and market visibility.

Why Brand Identity and Storytelling Matter

In the B2B world—particularly in automotive, consumer electronics, and home improvement—product quality is only half the equation. Buyers also need a brand they can trust. A name that signifies consistency, warranty integrity, after-sales support, and alignment with modern values (like sustainability or user-centric design).

Taiwanese firms have recognized this shift. They are no longer just creating reliable hardware—they are building emotional and professional trust around their products through:

- Consistent visual identity across packaging, catalogs, and online platforms

- Marketing messages tailored to pain points of specific B2B buyers (e.g., fleet managers, e-commerce sellers, OEM sourcing teams)

- Heritage storytelling that reinforces their origin, expertise, and production culture

For instance, Okjaws leverages its nearly 50-year history, combining that legacy with modernized visuals, multilingual packaging, and value propositions like “engineered for control, built to last.” This resonates with wholesalers and distributors who want more than just a commodity—they want a product with commercial value and brand leverage.

Content Marketing, Trade Shows, and DTC Expansion

To support their branding evolution, Taiwan’s manufacturers are investing in direct-to-consumer (DTC) infrastructure, content marketing, and global exhibitions:

- Content Marketing: From professional blog articles to YouTube installation videos and case studies, manufacturers are producing educational content that boosts SEO, builds trust, and shortens the sales cycle.

- International Trade Shows: Events like SEMA (USA), Automechanika (Germany/Shanghai), and Tokyo Auto Salon have become key stages where Taiwanese brands showcase not just products—but professionalism and brand sophistication.

- E-commerce and B2B platforms: Many firms now operate Shopify stores, Amazon listings, and Alibaba storefronts under their own brands, blending B2B and DTC outreach.

These multi-channel strategies amplify Taiwan’s global branding presence—allowing even niche manufacturers to position themselves as trusted premium partners in international markets.

Summary: Taiwan is rapidly evolving from a manufacturing hub into a powerhouse of brand creation. Companies like Giant, ASUS, and Okjaws are redefining “Made in Taiwan” to mean not only quality and engineering excellence—but also brand trust, design vision, and global relevance. Taiwan is no longer just a factory—it is a strategic force in global branding.

The Case of Okjaws: A Blueprint for Branding Taiwan-Made

As Taiwan continues to evolve into a symbol of quality-driven, brand-conscious manufacturing, few companies illustrate this transformation as clearly as Okjaws. Established in 1976 in Changhua, Taiwan, Okjaws is more than just a steering wheel knob producer—it is a case study in premium branding built on engineering precision, operational integrity, and global adaptability.

A Legacy of Manufacturing Excellence

With nearly five decades of continuous production, Okjaws has built a reputation around a core principle: engineering must serve both performance and safety. The company specializes in the development and production of steering wheel spinner knobs, a critical driving aid used by fleet drivers, seniors, delivery professionals, and anyone requiring enhanced steering control.

Unlike mass-market producers that rely on injection-molded plastic components, Okjaws differentiates itself with a zinc alloy die-cast base, precision-machined bearing mechanisms, and a screw-lock installation system designed to prevent loosening over time. Every component is subjected to stringent testing—impact durability, rotational smoothness, vibration resistance—to ensure it meets the expectations of global distributors and automotive professionals.

This level of craftsmanship positions Okjaws as a benchmark for Taiwan quality, delivering consistent product performance across thousands of units and over multiple generations of customers.

Tradition Meets Innovation

What truly sets Okjaws apart is its ability to blend traditional manufacturing expertise with modern product innovation and branding strategy. The company operates a fully integrated manufacturing setup, including:

- In-house R&D and tooling design teams

- Custom logo printing and brand personalization services

- Strict quality control protocols aligned with ISO standards

- Rapid prototyping for ODM and private-label clients

This vertically integrated approach enables Okjaws to respond quickly to evolving market needs—whether it’s a design revision for an OEM partner, a packaging refresh for a global distributor, or a new colorway for an Amazon bestseller. Every product is more than just functional—it’s engineered for control, built to last, and crafted to strengthen the brand it represents.

Global Positioning and Multi-Channel Appeal

Okjaws’ branding strategy is carefully built around trust, flexibility, and premium reliability—making it a preferred partner across several B2B buyer segments:

- Fleet buyers value the knobs’ durability and long-term safety performance under daily use.

- OEMs appreciate the ability to integrate custom logos and maintain brand consistency across vehicle lines.

- Amazon and e-commerce sellers benefit from ready-to-brand packaging, clear instructions, and low return rates.

- Offline distributors and automotive chains gain confidence in carrying a product that has decades of proven reliability and repeat customer demand.

What makes this even more compelling is that Okjaws doesn’t merely produce; it also supports partners with:

- Bilingual marketing assets

- Export-ready compliance documentation

- Collaborative product development processes

These value-adds elevate Okjaws from being just a factory to becoming a strategic partner in global branding.

Summary: Okjaws is a blueprint for what “Made in Taiwan” truly means in today’s B2B manufacturing landscape. By uniting legacy craftsmanship, modern engineering, and branding agility, Okjaws demonstrates how Taiwanese companies can lead not only in product quality but also in global brand equity. It is the embodiment of Taiwan’s evolution into a premium production and branding powerhouse.

Global Buyer Sentiment: Trust in Taiwan-Made

As global supply chains grow more volatile due to geopolitical tensions, raw material shortages, and regulatory complexity, B2B procurement strategies are being redefined. Today’s buyers are no longer focused solely on price and lead times—they are prioritizing trust, transparency, and long-term partnership. And increasingly, those priorities lead them to one country: Taiwan.

What the Data and Analysts Reveal

According to findings from B2B market trend analysts, sourcing managers across industries—from automotive to electronics to home improvement—consistently rank Taiwanese suppliers high in the following areas:

- Consistent quality control (QC) systems

- Clear, English-friendly communication

- Respect for contracts and intellectual property

- Responsiveness to customization and engineering changes

- Low rate of product returns and warranty claims

A 2023 survey by a leading supply chain consultancy found that 71% of North American sourcing managers rated Taiwan as “more trustworthy than regional peers” when asked about vendor reliability, IP protection, and QC transparency. The sentiment was echoed in Europe and ASEAN, where Taiwanese manufacturers were frequently chosen over competitors in China and Southeast Asia when product safety, compliance documentation, and end-user perception were at stake.

What B2B Buyers Really Care About

For professional buyers—whether from large distribution firms, Amazon storefronts, or automotive parts networks—Taiwanese manufacturers address multiple sourcing pain points:

- Communication clarity: English-speaking teams and professional documentation reduce back-and-forth and project delays.

- Stable quality control: Standardized processes, traceability, and ISO/IATF certifications lower the risk of inconsistent batches.

- Ethical business practices: Taiwan’s legal and business systems are built on transparency, making contracts enforceable and partnerships fair.

- Supply chain dependability: Taiwan’s infrastructure, supplier clustering, and export systems ensure strong delivery performance—even in crisis scenarios.

In contrast, many buyers express frustrations with low-cost competitors who promise flexibility but deliver inconsistency, communication breakdowns, or worse—IP theft or counterfeit risks.

Taiwan’s Strategic Advantage Amid Global Uncertainty

The sourcing landscape has fundamentally changed. U.S.–China tensions, rising tariffs, and forced labor legislation are pushing buyers to rethink their country-of-origin strategies. In this new reality, Taiwan stands out as a stable, democratic, and compliant hub that bridges Western business expectations with East Asian production efficiency.

Buyers in ASEAN markets, too, are turning to Taiwan for value-added partnerships. As e-commerce platforms and regional OEMs grow more brand-conscious, they seek manufacturers that can provide:

- Customization without chaos

- Compliance without compromise

- Brand-enhancing quality, not just cost savings

Taiwan delivers on all fronts. Manufacturers like Okjaws, for example, go beyond the transaction—offering:

- Private label support

- Branded packaging

- Fast iteration cycles

- Long-term inventory reliability

These are the factors that build brand trust downstream with consumers—and upstream with procurement teams.

Summary: Across markets in the U.S., EU, and ASEAN, sourcing managers are increasingly favoring Taiwanese partners for their predictable quality, business ethics, and long-term partnership reliability. In a global environment where uncertainty is the norm, “Made in Taiwan” offers peace of mind—and a powerful advantage in branding and supply chain performance.

Branding Beyond Borders: Strategies for Sustaining Global Reach

In today’s hyper-connected, competitive B2B landscape, great products are no longer enough. To win the trust of global buyers and retain long-term partners, Taiwanese manufacturers must evolve into global brand builders. This means combining engineering excellence with smart digital marketing, localized storytelling, and an omnichannel presence that resonates with diverse audiences.

Building a Digital-First Brand Strategy

Taiwanese exporters, including niche leaders like Okjaws, are increasingly investing in digital-first branding infrastructures that drive inbound interest, buyer confidence, and long-term loyalty. According to branding and content strategy frameworksbrand, five key pillars define global branding success:

- Digital Presence: A well-designed, multilingual website with rich product content, case studies, certifications, and technical downloads is now a baseline expectation. Mobile optimization, fast load speeds, and intuitive UX all contribute to international buyer confidence.

- Brand Storytelling: B2B buyers are human too—they connect with origin stories, quality missions, and behind-the-scenes views. Taiwanese brands that share their journey, factory values, and design philosophy outperform those that only push specs.

- Search Engine Optimization (SEO): Ranking on Google and B2B platforms like Alibaba or Made-in-China is essential. Content must be optimized with relevant keywords (e.g., “Taiwan quality steering wheel knob,” “ISO-certified automotive accessories”) across metadata, images, and internal links.

- Multilingual Content: English, Japanese, German, Spanish, and simplified Chinese content allow Taiwanese exporters to reach regional distributors and OEM buyers more effectively. Content should be culturally sensitive while reinforcing a consistent global brand voice.

- Customer Education: Through blogs, videos, and technical guides, Taiwanese manufacturers can position themselves as thought leaders—helping potential buyers understand not just what a product does, but why it outperforms competitors.

Power of Events and Platforms: Where Buyers and Brands Meet

While digital tools extend reach, face-to-face engagement and third-party validation still play critical roles in global B2B branding. Taiwanese brands that excel globally often combine:

- Global Exhibitions: Events like SEMA (USA), Automechanika (Germany, Shanghai, Dubai), and Tokyo Auto Salon give manufacturers visibility among automotive OEMs, distributors, and B2B press. Okjaws, for instance, uses these events to showcase product innovations and secure new market partnerships.

- Local Partnerships: Strategic alliances with regional importers, service centers, and marketing agents enable better last-mile delivery, localized customer service, and greater responsiveness to cultural nuances in branding and selling.

- Online B2B Platforms: Platforms like Alibaba, Global Sources, and ThomasNet remain vital lead-generation tools for Taiwanese exporters. What sets top-performing profiles apart is branding clarity: professional images, certifications, customer testimonials, and real-time communication features.

Summary: Building a global brand today means moving beyond the product and mastering the full spectrum of digital branding, strategic partnerships, and third-party trust signals. Taiwan’s best exporters, like Okjaws, succeed not only because they manufacture with excellence—but because they communicate it globally, consistently, and strategically.

What Global Buyers Should Expect from Taiwan Manufacturers

Global buyers—whether in procurement roles for OEMs, e-commerce platforms, or automotive chains—operate in a high-stakes environment where quality failures, missed deadlines, or poor communication can have far-reaching consequences. That’s why Taiwan has emerged as a preferred destination for premium sourcing partnerships: it offers not just products, but confidence.

When evaluating potential Taiwanese partners, sourcing teams should look for a combination of technical strength, business ethics, and strategic alignment. Here’s a quick checklist that reflects the distinguishing characteristics of Taiwan’s top-tier manufacturers:

Key Qualities to Look For in a Premium Taiwanese Supplier

- ISO/IATF Certifications

Reputable Taiwanese manufacturers comply with international standards such as ISO 9001 for quality management and IATF 16949 for the automotive industry. These aren’t symbolic badges—they reflect a company’s commitment to repeatable processes, product traceability, and continuous improvement. - Traceable Materials and Component Integrity

Unlike some lower-cost sourcing destinations, Taiwan-based factories use authenticated raw materials—from certified zinc alloys and plastics to proprietary bearings and electronics. Buyers can request traceability records and compliance declarations (e.g., RoHS, REACH) for each production batch. - In-House R&D and Tooling Capabilities

Manufacturers like Okjaws invest in their own engineering and prototyping teams, giving them the agility to co-develop products with clients. This allows for faster lead times, custom branding, and engineering refinement during pilot stages. - Strong IP Protection and Quality Control Frameworks

Taiwan’s legal and operational infrastructure offers robust intellectual property safeguards. NDA enforcement, CAD protection, and in-factory QC checkpoints ensure that your designs and standards remain secure—an increasingly critical factor in OEM relationships. - Responsive Post-Sales Support

Global distributors and retailers consistently praise Taiwanese partners for their after-sales professionalism. Whether it’s warranty handling, installation support, or long-term supply continuity, these manufacturers treat the relationship as a partnership—not a one-off transaction.

Business Peace of Mind, Not Just Technical Performance

What makes Taiwanese manufacturers like Okjaws stand out is their ability to enhance the brand equity of their buyers. By delivering:

- Lower return and defect rates

- Consistent customer satisfaction

- High-quality packaging and presentation

- Flexible MOQ with scalable production

They enable international distributors and retailers to build sustainable revenue streams with lower operational risk.

In practical terms, this means:

- E-commerce sellers benefit from 5-star product reviews and fewer refund disputes.

- Fleet procurement managers reduce replacement frequency and improve driver safety KPIs.

- OEMs gain assurance that their product extensions (e.g., co-branded accessories) will uphold their corporate reputation.

Taiwan’s best manufacturers don’t simply build products—they build trust, performance, and commercial value into everything they deliver.

Summary: When global buyers choose Taiwanese manufacturers, they aren’t just buying parts—they’re investing in technical reliability and strategic peace of mind. From ISO certifications to responsive support and material traceability, Taiwan offers a rare combination of precision, professionalism, and partnership that fuels long-term B2B success.

Conclusion: Taiwan’s Legacy Is Its Competitive Edge

For over five decades, Taiwan has quietly built a legacy of excellence in global manufacturing—a reputation grounded in precision, reliability, and ethical business practice. What began as a hub for OEM production has evolved into a strategic sourcing destination for global buyers who value consistency, innovation, and long-term brand protection.

From die-cast steering wheel knobs to semiconductors, from bicycles to smart devices, Taiwanese manufacturers have earned their place not only on the production line—but also in the boardrooms of leading global procurement teams. This enduring trust is a direct result of Taiwan’s unwavering commitment to:

- International certification and compliance

- Engineering-led innovation

- Transparent and responsive customer relationships

- A culture of continuous improvement

But Taiwan’s competitive edge is not stuck in the past—it is actively evolving for the future.

As the global economy shifts toward electric vehicles (EVs), connected mobility, smart automation, and sustainable supply chains, Taiwan is already adapting. Investments in green manufacturing, AI-driven production, and advanced materials are positioning Taiwanese factories at the forefront of the next industrial transformation.

Manufacturers like Okjaws are a microcosm of this shift—merging decades of hands-on craftsmanship with data-driven product design, customer-focused branding, and multi-channel distribution support. These are the capabilities that define not just a vendor—but a value-adding partner.

A Strategic Call to B2B Buyers

If you’re a B2B buyer—whether sourcing for OEMs, online marketplaces, automotive retailers, or fleet solutions—it’s time to see Taiwan for what it truly is:

- Not just a manufacturing base, but a branding partner

- Not just a component supplier, but a customer experience enhancer

- Not just a cost center, but a quality-driven growth engine

Partnering with Taiwan means anchoring your supply chain in a country where product excellence and brand credibility converge.

“Made in Taiwan” is not a label—it’s a strategic advantage. Use it. Build on it. Grow with it.